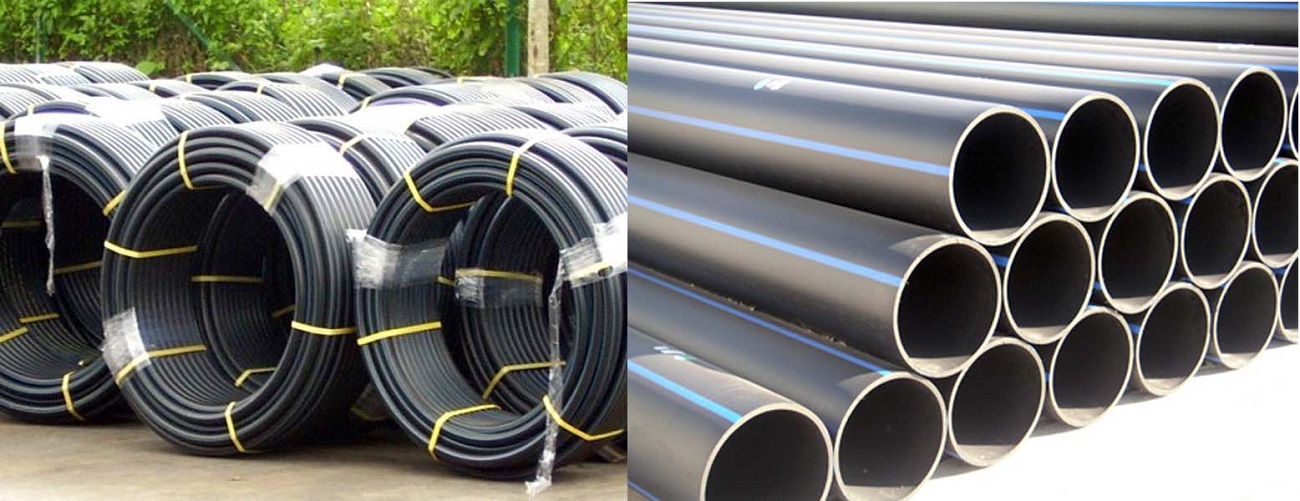

There are so many polyethylene(PE) pipe manufacturers, with good and bad are mixed, Users are difficult to distinguish when they choose the polyethylene(PE) pipe manufacturers and the polyethylene(PE) pipes they produce. So how to choose a suitable polyethylene(PE) pipe manufacturer and polyethylene(PE) pipe production needs to be considered from the following perspectives.

From the perspective of users, we buy PE pipes produced by polyethylene(PE) pipe manufacturers to choose high-quality and low-cost products, which can withstand the test of time, withstand the use of users, and meet the psychological expectations of users. Then this polyethylene(PE) pipes are the qualified products in the minds of users.

From the perspective of users, when we buy polyethylene(PE) pipes, we prefer to high-quality and low-cost products that can withstand the test of time, have long time service life, and meet the psychological expectations of users. This is the qualified products the customer want.

For polyethylene(PE) pipes produced by polyethylene(PE) pipes manufacturers on the market, users should pay attention to the following items when selecting:

For detailed introduction of polyethylene(PE) pipe products, instructions for use, questions, etc., check the polyethylene(PE) raw materials to avoid unscrupulous manufacturers from using low-priced and substandard polyethylene(PE) raw materials.

According to the introduction of the production equipment of polyethylene(PE) pipe manufacturers, there is a big difference between the production equipment of domestic advanced polyethylene(PE) pipe manufacturers and the low-end production equipment. Bingo Pipeline adopts the Barton Heidfeld automatic production line from Germany, completed with a unique die design and an advanced extrusion system and a feeding system to ensure that the raw materials are fully plasticized, and the product stability is higher.

Check the testing standards. Even if good polyethylene(PE) raw materials are used, if the PE pipe produced by the polyethylene(PE) pipe manufacturer does not meet the national requirements, or the test does not meet the requirements, it does not meet the national mandatory standards, then the polyethylene(PE) pipe will be damaged during later using. Leakage and other issues will be very troublesome to repair again, so users should pay more attention to the testing capabilities and testing procedures of the polyethylene(PE) pipe manufacturer when choosing.

In summary, these are the points we should pay attention to when choosing a polyethylene(PE) pipe manufacturer. As long as we ensure good raw materials and strict production quality control procedures, we can ensure that the polyethylene(PE) pipes produced are qualified. Regarding our raw material control and For quality control system in the production process, please see about us for more information.

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.