Products+

Latest Products

Contact Us

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Tel: +86 371 8618 0298

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

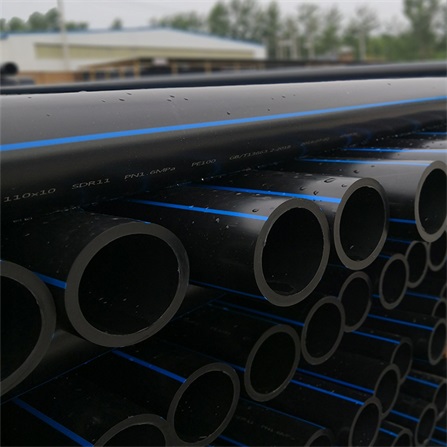

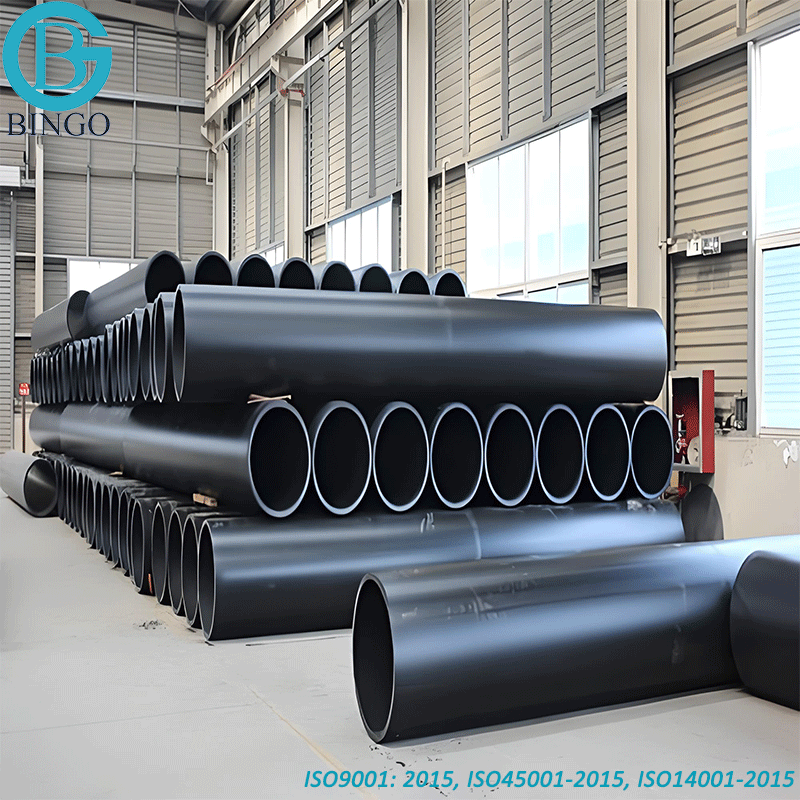

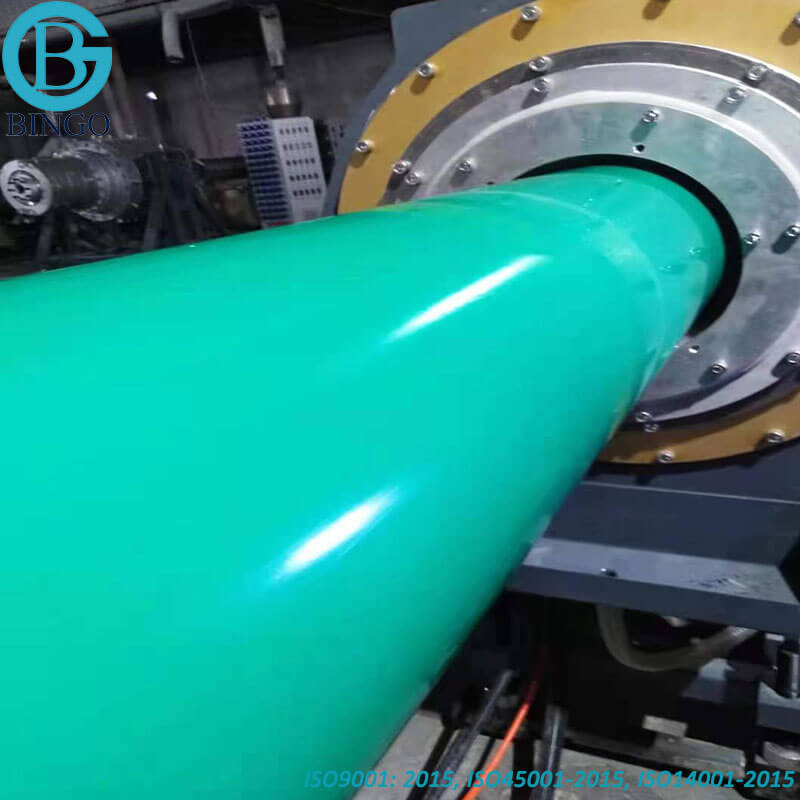

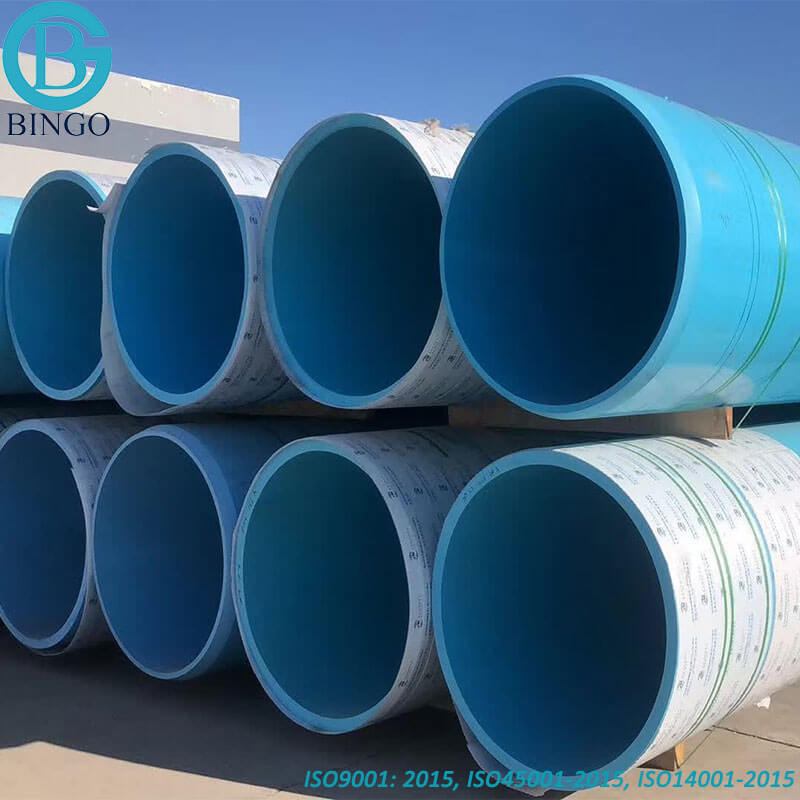

Modified Polyvinyl Chloride (PVC-M) Pipes

The performance improvement of the toughened modified polyvinyl chloride(PVC-M) pipe is significant. Mainly manifested in the improvement of design stress and toughness, impact resistance and cracking resistance. The toughness of PVC-M pipe is comparable to that of PE pipe. At the same time, it is also valuable for certain applications because it can tolerate a certain degree of bending deformation. It could be used for laying and repairing without excavation.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: 5.8m or 11.8m/ Pcs for straight, with plain ends or SCJ end.

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of Modified Polyvinyl Chloride (PVC-M) pipes

| Products details information | |

| Product name | Modified Polyvinyl Chloride (PVC-M) pipes |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-800mm(1/2 inch-32 inch) |

| Pressure Class | from PN8 to PN25 and Non Pressure PVC Pipe |

| Raw material | M PVC... |

| Application | PVC Pipes& fittings for drinking water, fresh water, portable water... |

| Color | Grey, Blue, others colors is option |

| Standards | ISO/DIS 16422... |

| Matching products | PVC fittings, Solvent Cement fittings, Rubber Ring Joints, Flanges, Glue and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of Modified Polyvinyl Chloride (PVC-M) pipes

PVC-U pipes have poor impact resistance in daily engineering applications, so that there are many unsafe factors in the application process, which indirectly reflects the shortcomings of PVC-U pipes are high brittleness and poor cracking and impact resistance. The main method for toughening modification of PVC is to add impact modifiers in the PVC formula to make the material have good toughness and improve the ability of the pipe to resist load. When the impact modifier is added to a certain amount of PVC, its toughness will reach a transition, that is, from a complete brittle fracture to an incomplete ductile fracture, achieving super toughness, and its toughness is increased many times. When this super-tough PVC mixture is applied to plastic water supply pipes to make PVC-M pipes (also known as PVC-A pipes), the use coefficient will be greatly improved, and the design stress will be greatly improved. For toughened and modified PVC M pipes, different countries use different names. The United States and Australia called PVC-M, Japan and the Netherlands called high-impact PVC pipes PVC-HI, and the United Kingdom named PVC-A.

Advantages of Modified Polyvinyl Chloride (PVC-M) pipes

In addition to the advantages of PVC U, such as light weight, good water tightness, sanitation, convenient construction and installation, and long service life, PVC M also has its unique toughness, impact resistance, environmental cracking resistance, chemical resistance, etc. It can be widely used in drinking water transmission and distribution pipe network and industrial and agricultural production water pipe network.

1. Excellent toughness, impact resistance, high burst resistance, and environmental rupture resistance.

2. It is light in weight, easy to store, install, and transport, and can effectively resist point loads and uneven foundation settlement, reducing safety hazards and increasing economic benefits.

3. Excellent anti-water hammer and anti-fatigue properties. Because of the good impact resistance, it can effectively resist water hammer, reduce the damage of the pipeline during operation, Increased economic benefits.

4. Light weight and low consumables. Due to the increased strength of the material, the wall thickness of the pipe is reduced. Compared with the PVC U pipe of the same pressure level, the weight is lighter.

5. Strong chemical resistance, can be applied to any common applications of PVC U pipe and fittings.

6. Strong water delivery capacity. Compared with PVC-U pipes of the same specification, high impact polyvinyl chloride (PVC-M) pipes have a larger flow rate.

Specification of Modified Polyvinyl Chloride (PVC-M) pipes

| Nominal Outside Diameterdn | Pipe Series S and Nominal Pressure PN | Rubber Ring Joints(RRJ) Minimum Socket Depth mmin | Solvent Cement Joints(SCJ) Minimum Socket Depth mmin | ||||

| S20 | S16 | S12.5 | S10 | S8 | |||

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | |||

| PN8 | PN10 | PN12.5 | PN16 | PN20 | |||

| Nominal Wall Thickness en | |||||||

| 63 | 2.0 | 2.0 | 2.5 | 3.0 | 3.8 | 64.0 | 37.5 |

| 75 | 2.0 | 2.3 | 2.9 | 3.6 | 4.5 | 67.0 | 43.5 |

| 90 | 2.2 | 2.8 | 3.5 | 4.3 | 5.4 | 70.0 | 51.0 |

| 110 | 2.7 | 3.4 | 4.2 | 5.3 | 6.6 | 75.0 | 61.0 |

| 125 | 3.1 | 3.9 | 4.8 | 6.0 | 7.4 | 78.0 | 68.5 |

| 140 | 3.5 | 4.3 | 5.4 | 6.7 | 8.3 | 81.0 | 76.0 |

| 160 | 4.0 | 4.9 | 6.2 | 7.7 | 9.5 | 86.0 | 86.0 |

| 180 | 4.4 | 5.5 | 6.9 | 8.6 | 10.7 | 90.0 | 96.0 |

| 200 | 4.9 | 6.2 | 7.7 | 9.6 | 11.9 | 94.0 | 106.0 |

| 225 | 5.5 | 6.9 | 8.6 | 10.8 | 13.4 | 100.0 | 118.5 |

| 250 | 6.2 | 7.7 | 9.6 | 11.9 | 14.8 | 105.0 | - |

| 280 | 6.9 | 8.6 | 10.7 | 13.4 | 16.6 | 112.0 | - |

| 315 | 7.7 | 9.7 | 12.1 | 15.0 | 18.7 | 118.0 | - |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 124.0 | - |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 130.0 | - |

| 450 | 11.0 | 13.8 | 17.2 | 21.5 | 26.7 | 138.0 | - |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 145.0 | - |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | - | 154.0 | - |

| 630 | 15.4 | 19.3 | 24.1 | 30.0 | - | 165.0 | - |

| 710 | 17.4 | 21.8 | 27.2 | - | - | 177.0 | - |

| 800 | 19.6 | 24.5 | 30.6 | - | - | 190.0 | - |

| 1: The minimum required strength of the pipe is not less than 24.5MPa, the nominal wall thickness (en) is determined according to the design stress (as) 16MPa, and the minimum wall thickness of the pipe is 2.0mm. 2:“-” Indicates not recommended. 3:When the length of the pipe is longer than 12 m, the rubber ring joints socket depth mmin needs to be designed separately. | |||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Applications of Modified Polyvinyl Chloride (PVC-M) pipes

- Potable water supply trunk and reticulation mains

- Industrial process pipelines

- Effluent pipes for pumped sewage, industrial and rural wastes

- Slurry pipelines carrying abrasive and corrosive mine or quarry materials

- Irrigation and turf watering systems

- Mine pipeline (South Africa)

- Liner pipe for trenchless laying and repair (United States)

- Used in earthquake conditions (Japan)

- For low-pressure gas transmission and distribution (Netherlands)

|

|

| M PVC for Urban Water Supply | M PVC Pipes for Subsoil Drainage System |

|

|

| M PVC for Sewage Treatment System | M PVC Pipes for Water Supply |

Modified Polyvinyl Chloride (PVC-M) pipes

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español