Products+

Latest Products

Contact Us

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Tel: +86 371 8618 0298

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

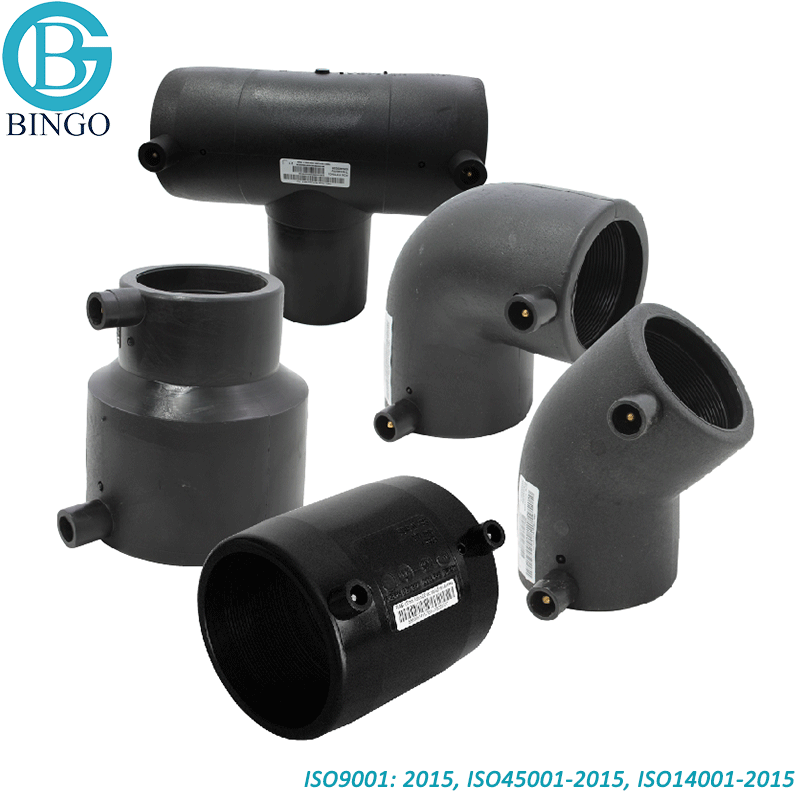

HDPE Electrofusion Welding Fitting with Bar Code

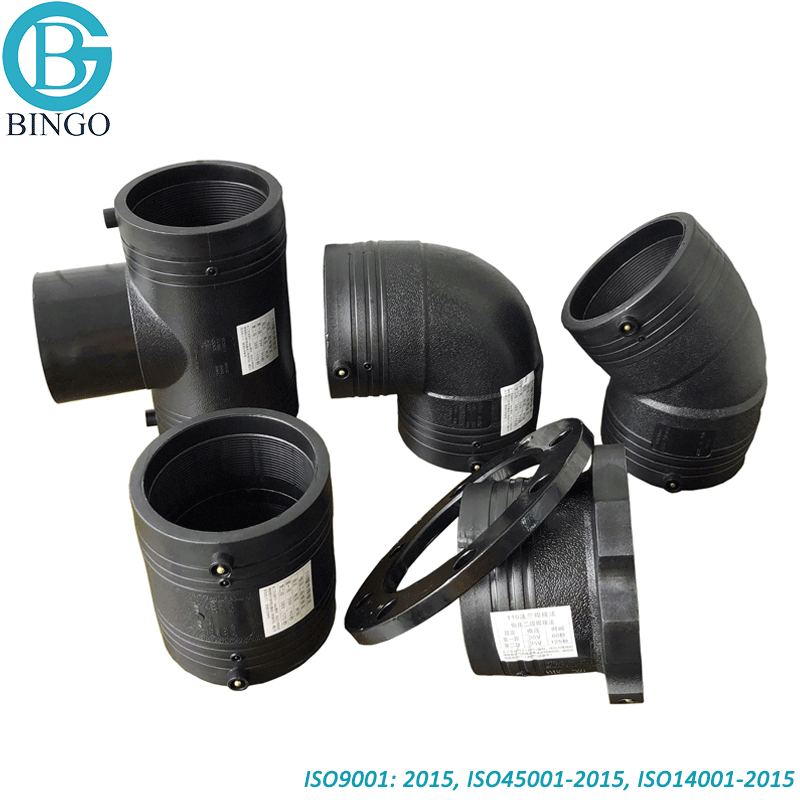

Electrofusion fittings are available in a range of forms; they may be straight connectors, bends, tees, stop ends, reducers, saddle fittings and repair fittings.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: Packaged by cartons or bags

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) electro fusion welding fitting with bar code

| Products details information | |

| Product name | High Density Polyethylene (HDPE) electro fusion welding fitting with bar code |

| Brand | Bingo pipeline(Customer brand is available) |

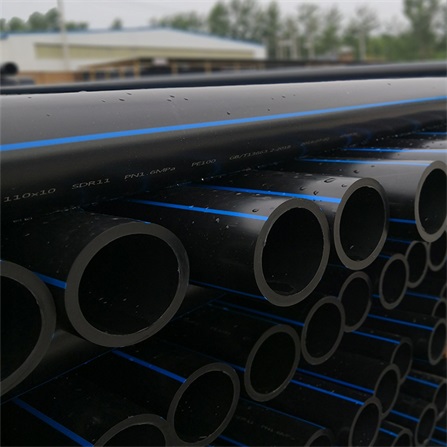

| Dia Ranges | DN20-630mm(1/2 inch- 25 inch) |

| Pressure Class | from PN10 to PN16 |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | HDPE Fittings for water, oil and gas, mining, marine, drainage, chemincal, Irrigation, fire fighting... |

| Color | Black |

| Category | HDPE Electro fusion fittings, stub end, tee, elbow, reducer, reducer tee, cross... |

| Matching products | HDPE pipe fittings, Customized PE fittings, DI/ Steel backing ring flanges, Valves, water meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

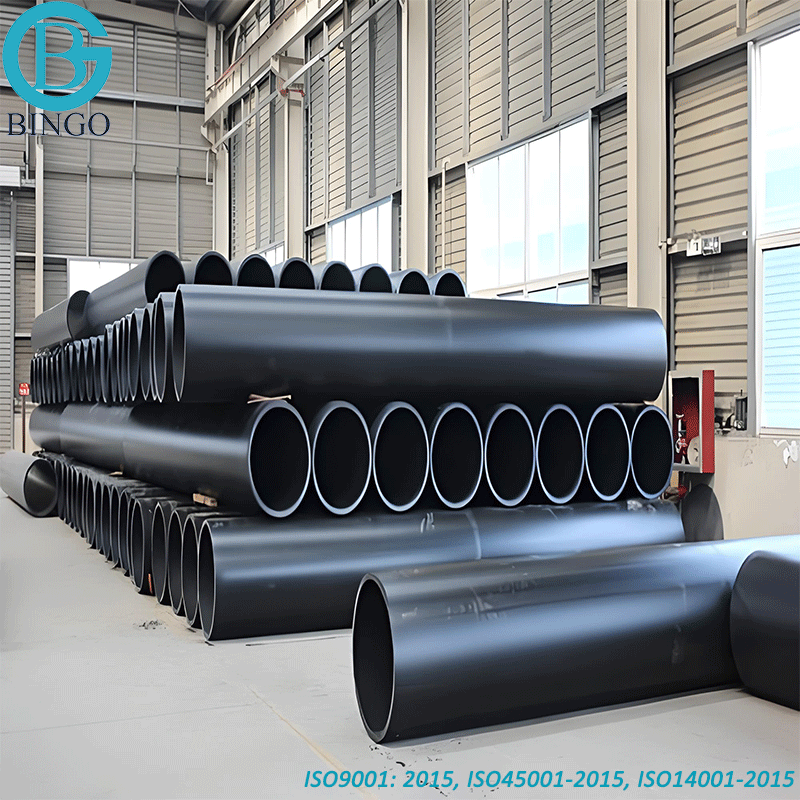

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) electro fusion welding fitting with bar code

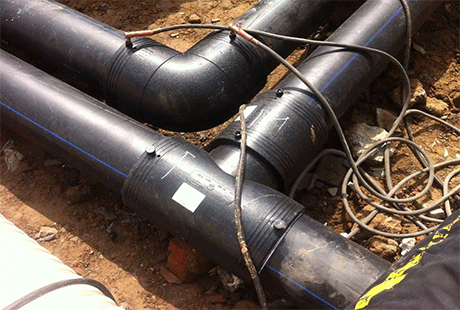

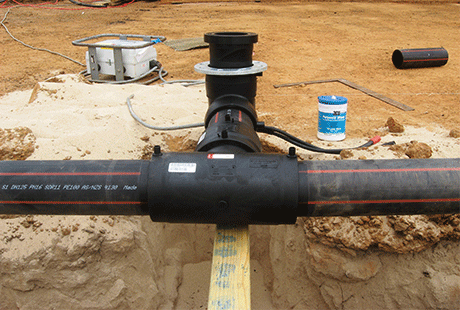

Electrofusion is most commonly used for jointing pipes up to 250mm diameter but there is no technical upper limit. It is nevertheless most commonly used for smaller diameter pipes because the cost of fittings increases with diameter. Electrofusion is equally suited to both coiled and straight pipe lengths, and can be used to joint pipes of different nominal diameters and SDR's using suitable fittings.

Electrofusion is most commonly used in conventional open cut trenching installation, and in repair works. It is also used for adding new services to existing PE mains by means of saddle fittings or tees. It is less well suited to trenchless installation or rehabilitation methods because the fittings protrude on the outside of the pipe.

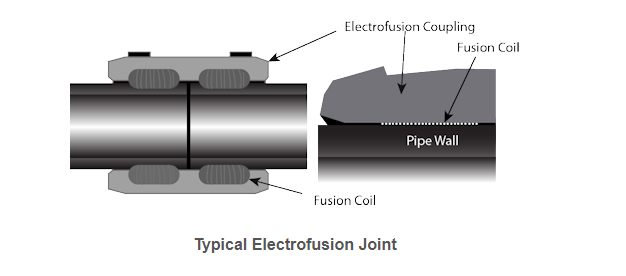

Electrofusion is a method of joining PE pipes using fittings with integral heating elements.

Sockets fittings are used to join mains and service pipes; and saddle fittings are used to connect services to mains. Electrofusion fittings are available in a range of forms; they may be straight connectors, bends, tees, stop ends, reducers, saddle fittings and repair fittings.

Electrofusion fittings are particularly suited to installations where access is difficult, such as in trenches or around other pipes.

The main difference between conventional heat fusion and electrofusion is the method by which the heat is applied. In conventional heat fusion (butt, saddle and socket) joining, a heating tool is used to heat the pipe and fitting surfaces. The electrofusion joint is heated internally, either by a conductor at the interface of the joint or by a conductive polymer. Heat is created as an electric current is applied to the conductive material in the fitting. PE pipe to pipe connections made using the electrofusion process require the use of electrofusion couplings.

About the electrofusion, please check the standard electrofusion guidance: ASTM F1290-19, Standard Practice for Electrofusion Joining Polyolefin Pipe and Fittings, ASTM International.

Advantages of High Density Polyethylene (HDPE) electro fusion welding fitting with bar code

easy welding procedure

simple preparation of the weld

easy handling − constant quality of the weld

no welding bead inside the pipe

welding in difficult locations possible

axial load connection

usable for a wide range of dimensions

Specification of High Density Polyethylene (HDPE) electro fusion welding fitting with bar code

| Item | Fittings Types | Specified Fittings | Diameter(mm) | Pressure Rates(PN-Bar) | Manufacturing Process |

| 4 | Electrofusion Fittings | EF Coupler/Coupling | OD50-630mm | PN16, PN12.5, PN10 | Injection Molding |

| EF Reducer/ Reducing Coupler | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF 45 deg elbow | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF 90 deg elbow | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF End Cap | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF Stub End | OD50-800mm | PN16, PN12.5, PN10 | |||

| EF Tee | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF Reducer Tee | OD50-630mm | PN16, PN12.5, PN10 |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

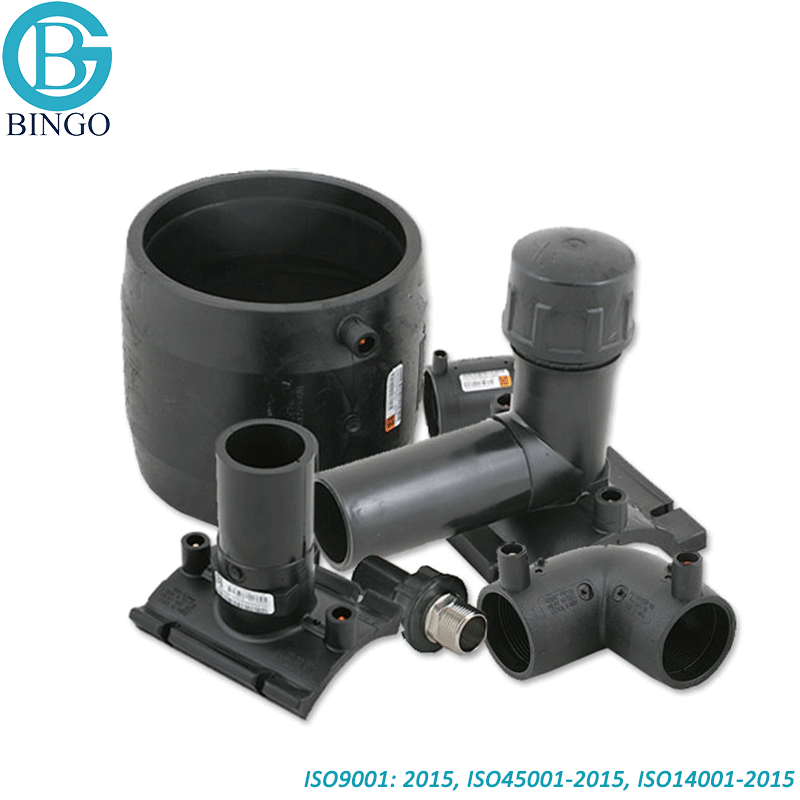

HDPE Electro Fusion Fittings DN20-800mm PN10 and PN16 for Water and Gas

| Injection Molded HDPE Electro Fusion HDPE Fittings | ||||

|

|

|

|

|

| HDPE 45° Elbow | HDPE 90° Elbow | HDPE Stub End | HDPE Tee | HDPE Reducer Tee |

|

|

|

|

|

| HDPE End Cap | HDPE Reducer | HDPE Coupler | HDPE Tapping Saddle | HDPE Branch Saddle |

Please Contact us to Get More Details, Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Applications of High Density Polyethylene (HDPE) electro fusion welding fitting with bar code

- HDPE Water supply system

- PE Drainage, sewer pipes

- HDPE Pipeline for Oil and Gas

- Industrial area applications

- Mining projects

|

|

| HDPE Pipes for Reclaimed Water Transfer | HDPE Pipes for Collection Of Methane |

|

|

| HDPE Pipes for Industrial Area Applications | HDPE Pipes for Municipal Fire Protection |

High Density Polyethylene (HDPE) electro fusion welding fitting with bar code

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español