Products+

Latest Products

Contact Us

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Tel: +86 371 8618 0298

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

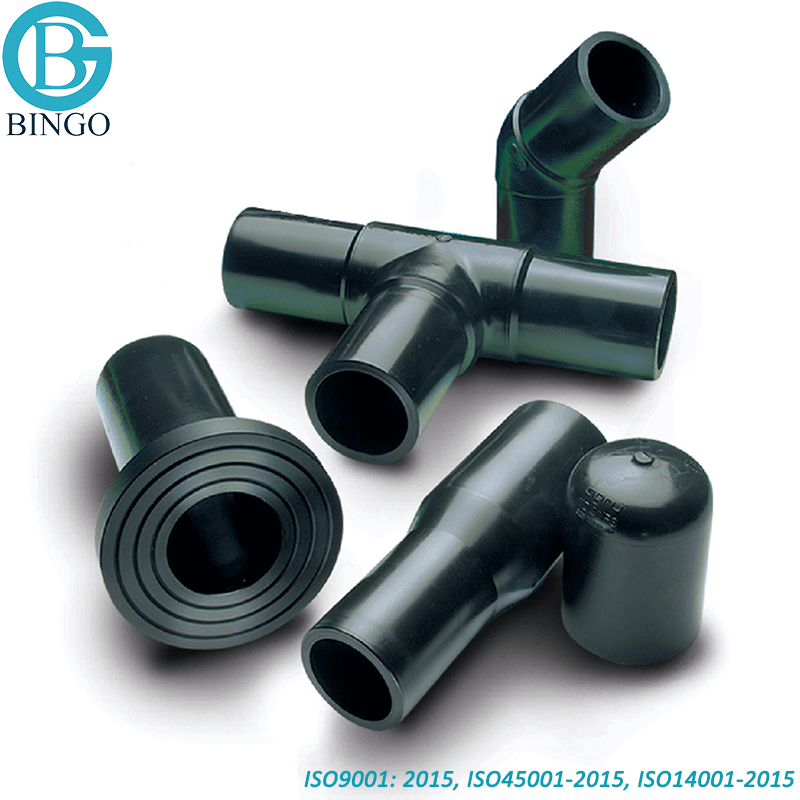

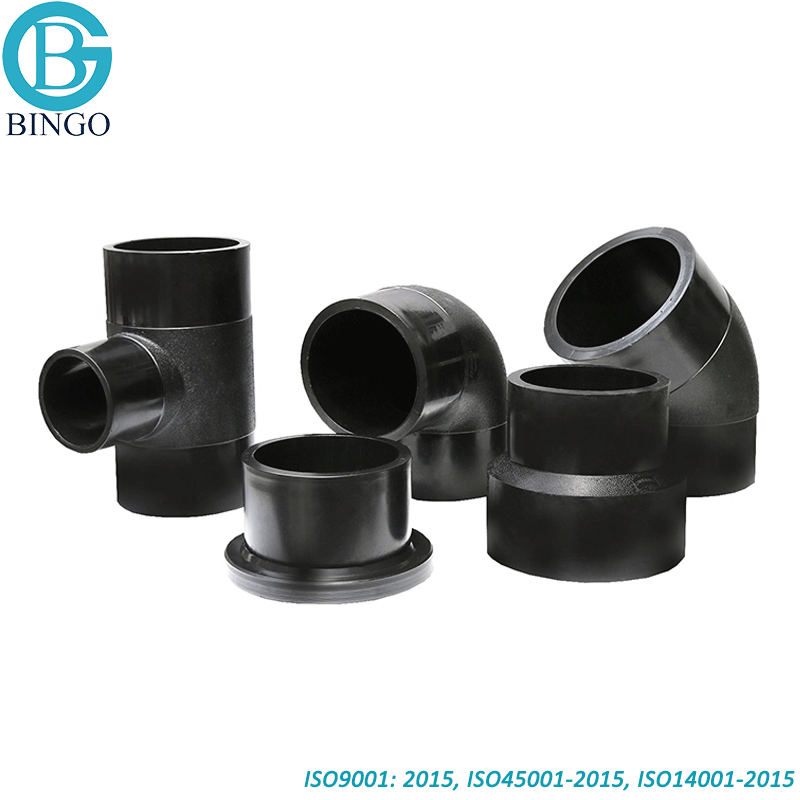

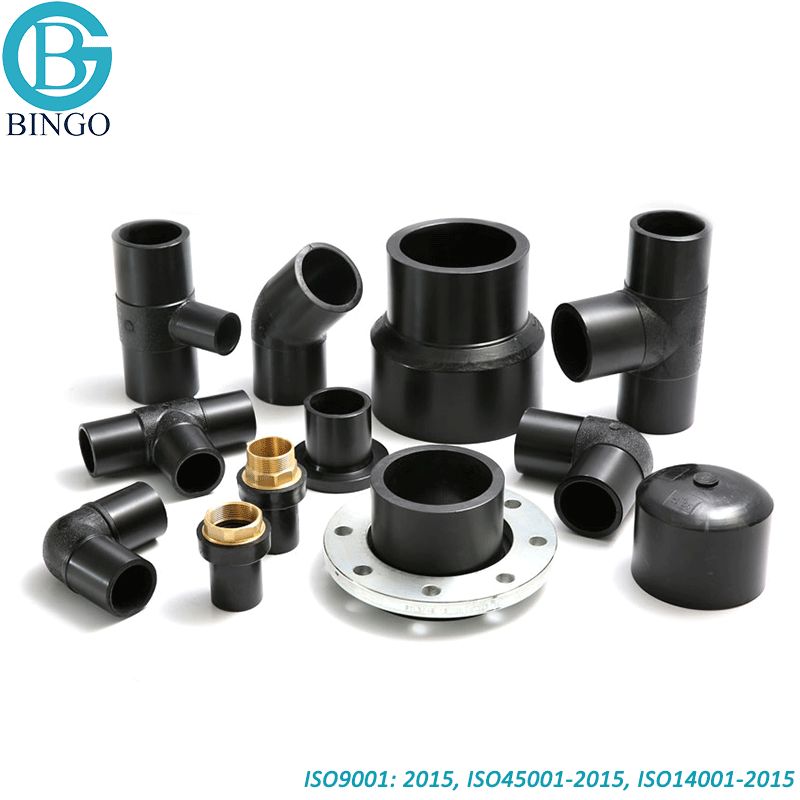

HDPE Fittings Butt Fusion Welding Fitting

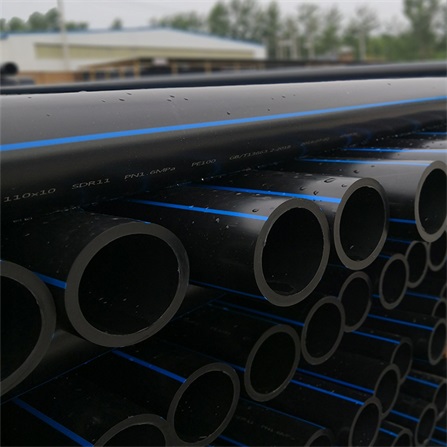

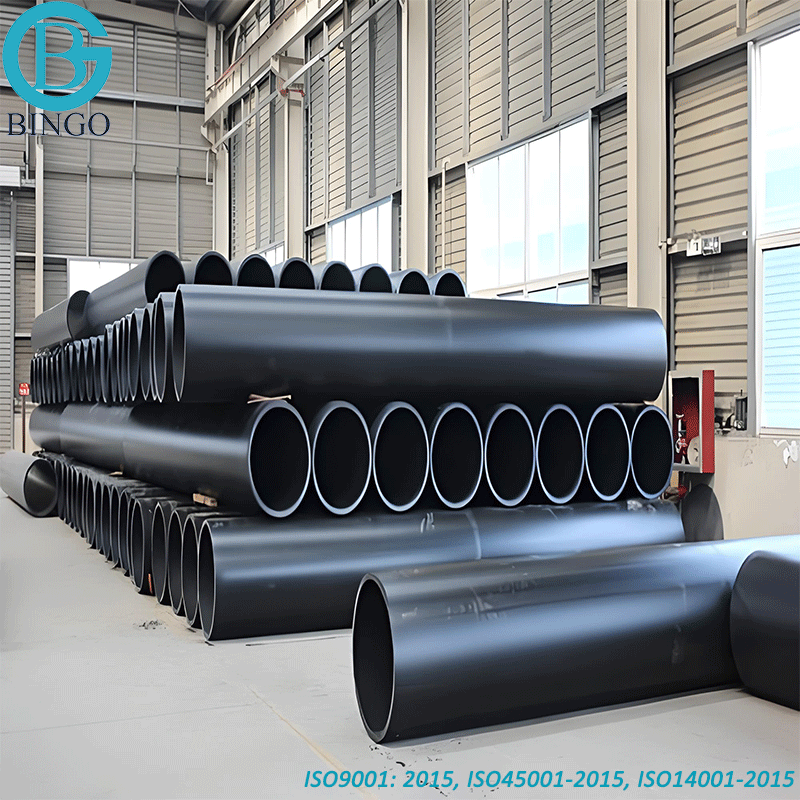

Bingo Pipeline has a wide range of butt fusion welding HDPE fittings in accordance with the ISO 4427, EN12201,AS/NZS 4129 PE Fittings, ISO4437 standards etc. From the diameter OD50 to 1200mm.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: Packaged by cartons or bags

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) butt fusion welding fitting

| Products details information | |

| Product name | High Density Polyethylene (HDPE) butt fusion welding fitting |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Pressure Class | From PN10 to PN32 |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | HDPE Fittings for water, oil and gas, mining, marine, drainage, chemincal... |

| Color | Black or Blue |

| Category | Butt fusion fittings, stub end, tee, elbow, reducer, reducer tee, cross... |

| Matching products | HDPE pipe fittings, Customized PE fittings, DI/ Steel backing ring flanges, Valves, water meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) butt fusion welding fitting

Bingo Pipeline has a wide range of butt fusion welding HDPE fittings in accordance with the ISO 4427, EN12201,AS/NZS 4129 PE Fittings, ISO4437 standards etc. From the diameter OD50 to 1200mm, could be used for water supply, oil and gas transmission. The pressure rate PN10, PN12.5, PN16, PN20, PN25 are available for options.

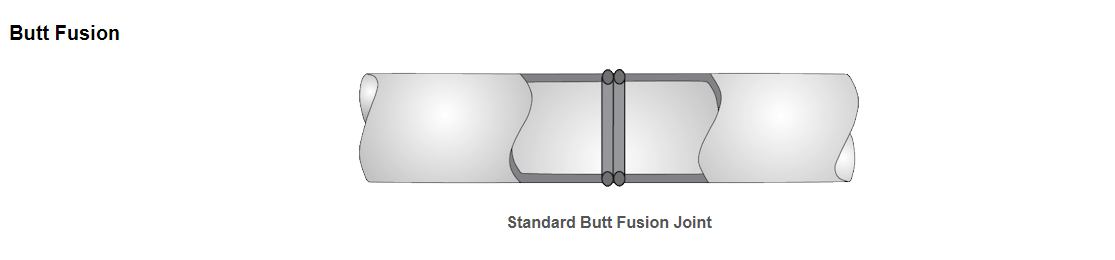

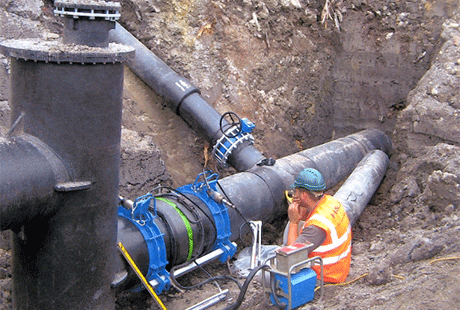

Butt fusion can be used for jointing pipes and fittings 63mm diameter and larger. However it is most commonly used for larger diameter pipes. Butt fusion jointing is equally suited to both coiled pipes and straight pipe lengths. Only pipes and fittings of the same nominal diameter may be butt fused.

Description of High Density Polyethylene (HDPE) butt fusion welding fitting

Butt fusion can be used in new installations using traditional open cut trenching techniques. Additionally due to the low profile of the butt joint it is ideal for use in trenchless technology installations, sliplining, pipe bursting, directional drilling, etc.

Please check above list and find our butt fusion fittings type and the diameter & pressure class ranges. These fittings are safe and reliable for a range of applications across many different industries.

All the PE butt fusion fittings are made from the PE100 material, same with the pipes. Butt fusion end PE pipes can be joined by butt fusion thus avoiding the need for a fitting. Some spigot end fittings like tee, elbow, end cap, stub ends and so one are produced specifically for butt fusion to pipe. These must be specified to match both the pressure rating and the SDR of the pipe. It is normally not acceptable to use a butt fusion fitting of a different SDR rating to that of the pipe even if the pressure rating of the fitting is equivalent or higher than that of the pipe.

PE pipes of the same outside diameter but having different specified wall thicknesses (i.e., different DR designations) may be butt fused to each other under special conditions, but is subject to limitations, requiring consultation with the pipe manufacturer.

In some pipe systems, engineers may elect to remove the inner or outer bead of the joint, using appropriate tools and procedures. Since the fusion must be completely cooled before bead removal, assembly time is increased slightly. However, it is uncommon to remove internal beads, as they have little or no effect on flow, and removal is more time-consuming, requiring use of a cutter fitted to a long pole following each fusion.

The most widely used method for joining individual lengths of PE pipe and pipe to PE fittings is by heat fusion of the pipe butt ends (butt fusion). This technique produces a permanent, economical and flow-efficient connection. PPI Technical Report TR-33, Generic Butt Fusion Joining Procedure for Field Joining of Polyethylene Pipe and ASTM International F 2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings and ASTM International F 2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings, provide recommended practices for the generic butt fusion joining procedure. And the ISO21307 Standards,Plastics pipes and fittings — Butt fusion jointing procedures for polyethylene (PE) piping systems

Characteristics And Advantages of High Density Polyethylene (HDPE) butt fusion welding fitting

The two surfaces are then brought together under controlled pressure for a specific cooling time and a homogeneous fusion joint is formed. The resultant joint is fully resistant to end loads and has comparable performance under pressure to the pipe itself, which is as strong as the original pipe and can withstand all the loads applied during routine installation and operation.

High durability. Can be used for a diverse range of applications

Non-corrosive, chemical resistant

Leak free due to high quality butt welding, Available in a wide range of thicknesses and pressure ratings

Light weight and flexible for easier and more cost effective freight, handling and installation.

Specification of High Density Polyethylene (HDPE) butt fusion welding fitting

| Item | Fittings Types | Specified Fittings | Diameter(mm) | Pressure Rates(PN-Bar) | Manufacturing Process |

| 3 | Butt Fusion Fittings | Male Union | OD20-63mm 1/2'-2' | Injection Molding | |

| Reducer/ Reducing Coupler | OD75-630mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| Tee | OD63-630mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| Reducer Tee | OD75-630mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| 90 deg elbow | OD63-630mm | PN16, PN12.5, PN10 | |||

| 45 deg elbow | OD63-630mm | PN16, PN12.5, PN10 | |||

| 30 deg elbow | OD63-630mm | PN16, PN12.5, PN10 | |||

| 22.5 deg elbow | OD110-630mm | PN16, PN12.5, PN10 | |||

| End Cap | OD75-1200mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| Cross Tee | OD63-315mm | PN16, PN12.5 | |||

| Reducer Cross Tee | OD90-315mm | PN16, PN12.5 | |||

| Stub End | OD50-630mm | PN16, PN12.5, PN10 | |||

| Lateral Tee(45 deg Tee) | OD63-160mm | PN16 | |||

HDPE Butt Fusion fittings DN50-2000mm PN10 to PN25

| Injection Molded HDPE Butt Fusion HDPE Fittings | ||||

|

|

|

|

|

| HDPE 45° Elbow | HDPE 90° Elbow | HDPE Stub End | HDPE Tee | HDPE Reducer Tee |

|

|

|

|

|

| HDPE End Cap | HDPE Reducer | HDPE Y Tee 45° | HDPE Cross | HDPE Reducing Cross |

Please Contact us to Get More Details, Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Applications of High Density Polyethylene (HDPE) butt fusion welding fitting

PE fittings made from polyethylene is a cost effective solution for a broad range of piping system challenges in mining, industrial, mechanical, marine and agricultural applications. It has been tested and proven effective for above ground, surface, buried, sliplined, floating, and sub-surface marine applications.

High-density polyethylene pipe and fittings (HDPE) can carry:

- 1.potable water

- 2.wastewater

- 3.slurries

- 4.slurries

- 5.compressed gases

|

|

| HDPE Pipes for Waste Water Mains | HDPE Pipes for Rural Irrigation |

|

|

| HDPE Pipes for Mining Industry | HDPE Pipes for Urban Water Supply |

High Density Polyethylene (HDPE) butt fusion welding fitting

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español