Products+

Latest Products

Contact Us

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Tel: +86 371 8618 0298

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

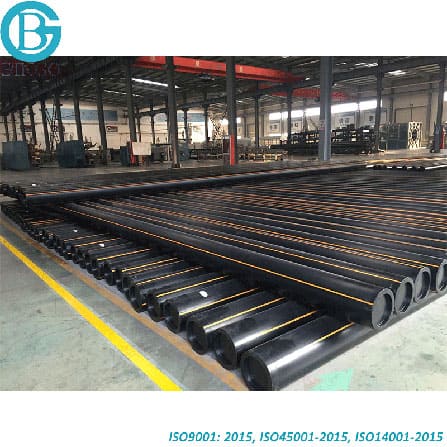

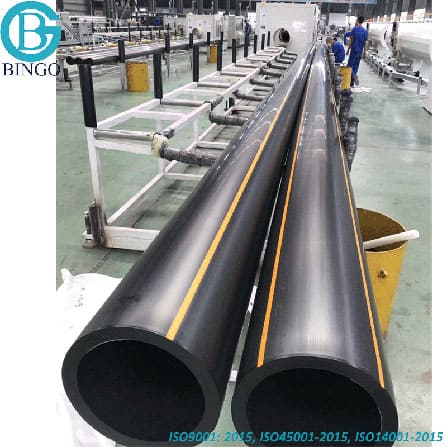

HDPE Pipes and Fittings for Natural Gas & Oil

- 1.Delivery: 10-30 days depending on the total quantity.

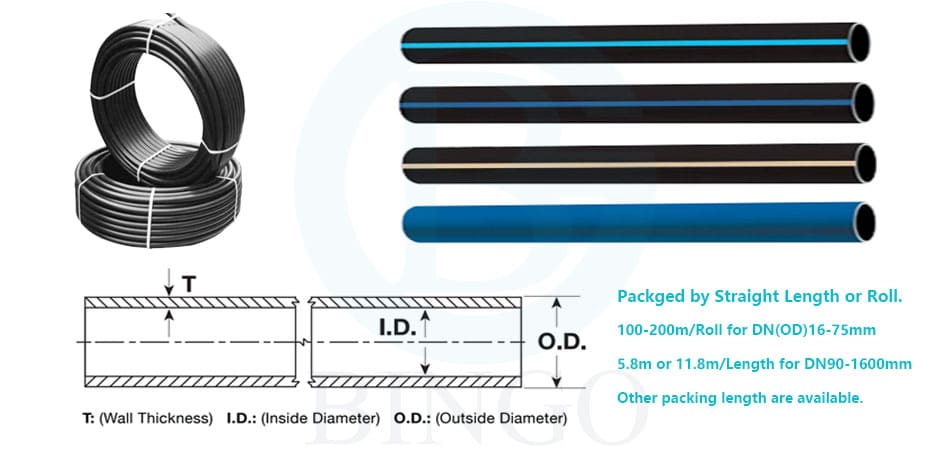

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings

| Products details information | |

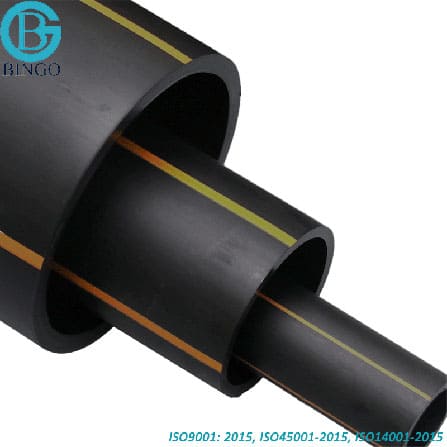

| Product name | High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-630mm(1/2 inch-24 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | oil, natural gas, methane... |

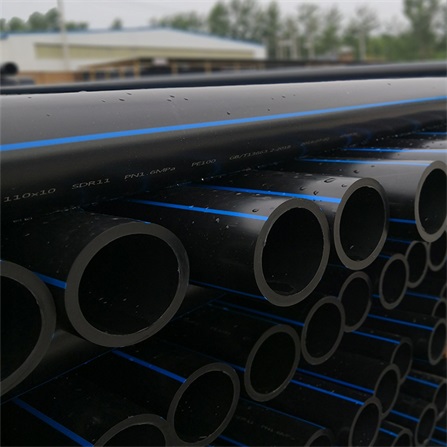

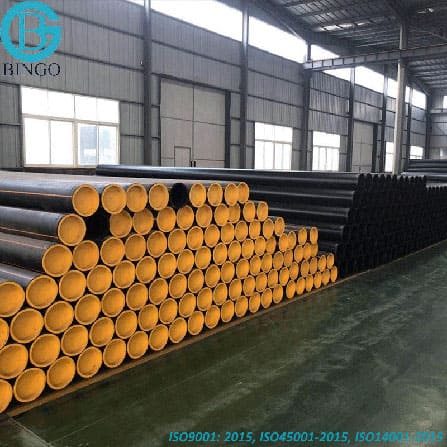

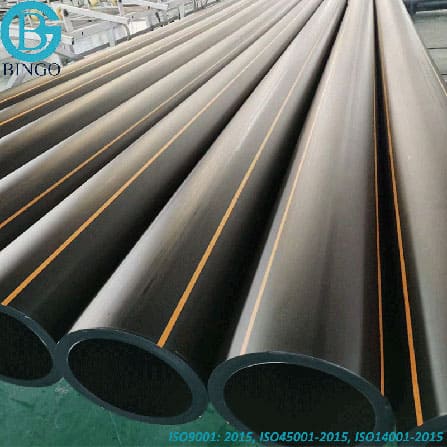

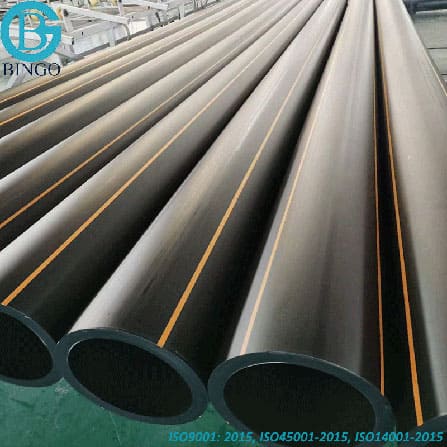

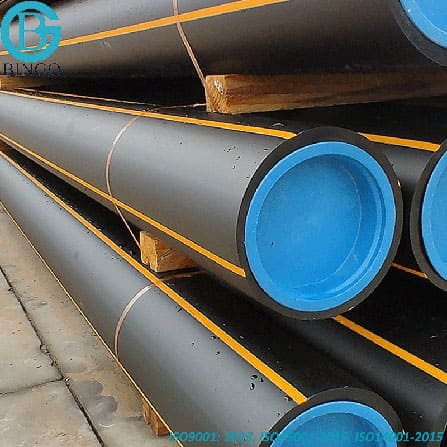

| Color | Black with yellow stripes, yellow or others colors |

| Standards | ISO4437, EN1555, GB/T15558, ASTM D3035, AS/NZS4130, GOST18599, ASTM D2513... |

| Matching products | HDPE pipe fittings, DI/ Steel backing ring flanges, Valves, gas meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

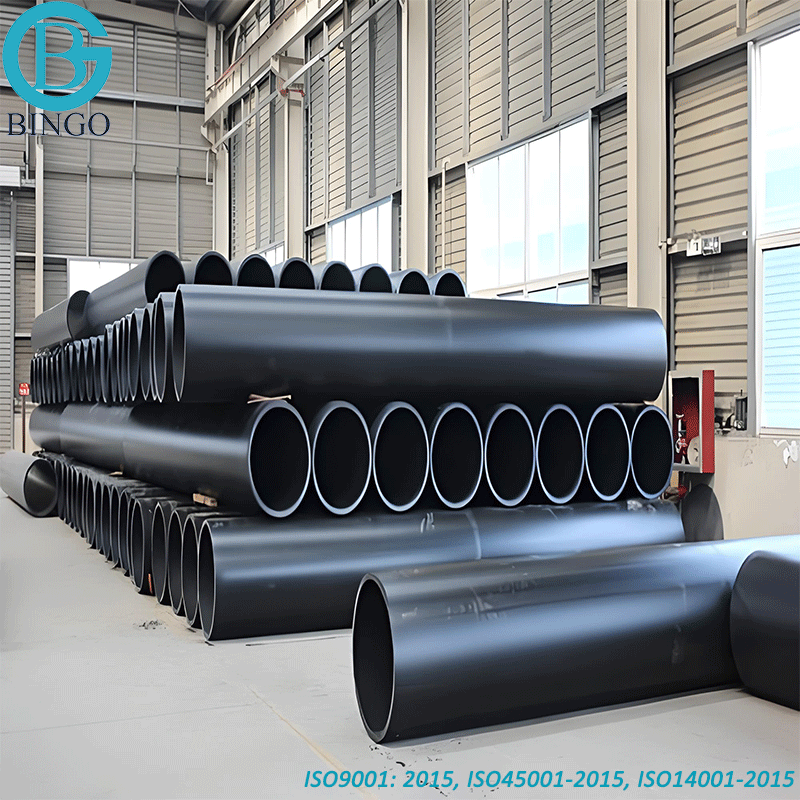

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings

Today HDPE, polyamide and advanced spoolable composite piping represent a large portion of the oil & gas gathering market in the worlds.

The use of HDPE piping in oil and gas applications is not new, but has grown dramatically in recent years mainly due to its’ ability to withstand demanding service conditions over a long period of time. That growth has greatly increased the number of end users that may be using HDPE pipe for the first time, or may have limited knowledge about how to specify, inspect, and qualify the HDPE products they use.

When specifying a polyethylene pipe for oil and gas applications it is critical to specify the qualified materials and to ensure that the pipe is sourced from a manufacturer that has a demonstrated capability to produce pipe that meets or exceeds industry standards. Industry standards require that a PE4710 or PE100 compounds be used in the manufacture of the HDPE pipe.

Bingo pipeline’s high density polyethylene (HDPE) PE4710 pipes or PE100 pipes are the ideal solution for oil & gas gathering applications, due to its leak-free joints, durability, cost-effectiveness, lightweight properties, and its resistance to hydrocarbon permeation. This allows PE4710 pipe or PE100 pipes to last longer than alternative metallic pipe materials without the need for coatings, corrosion prevention treatments and constant repairs. HDPE pipe is inherently resistant to chemical attack and corrosion, which eliminates the risk leakage. The interior of PE4710 pipe or PE100 pipes are smooth which reduces oil and gas ability to build up on the pipe surface over time.

|

|

|

|

Advantages of High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings

Bingo HDPE pipe for oil and gas has high impact resistance, even under low temperatures, and is resistant to corrosive chemicals and aggressive soils. It is a flexible product, easy to handle, install and joint fuse due to longer lengths and even surface finish. Other benefits include: corrosion resistance, extreme weather resistance, slow crack growth resistance, abrasion resistance, flexibility for earthquake prone areas, satisfactory fusion joints, and long service life. It could be apt to survive severe ground shifts, especially from earthquakes, when they are made from fused PE pipe joints.

1.Raw Material. Excellent performance of the pipes. HDPE oil and gas pipe is manufactured with 100% virgin PE4710 or PE100 bi-modal resin material that is classified according to the standard ISO 4437/ AS/ NZS 4130/ BS EN 1555/ SANS 8085/ D3350. HDPE (Poly) Piping is the most durable and resilient piping for oil and gas applications.

2.Joint Fuse. HDPE pipe for oil and gas distribution applications can be easily joined through diverse fusion methods, like electro-fusion, socket fusion, butt fusion, among other, at the discretion of the installation company. With proper installation methods, we will provide guaranteed leak free joints for approval.

3.Easy Installation. HDPE Pipe has long laying length, is light weight and highly flexible, adapting to irregular terrain and supporting dynamic loads. This reduces the need for further fitting requirements on directional changes, which in turn facilitates installation and reduces costs.

4.Quality Control. Bingo gas and oil pipe is tested in accordance with the applicable standards and specifications in an in-house accredited laboratory per ISO 17025. Additionally, the quality and performance of oil and gas pipe is tested and complies with extra internal requirements that meet and exceed customer expectations. Bingo pipeline is an ISO 9001:2018 certified company.

5.Long service life. Every pipe is rated to last 50-100 years. Never leaking, never breaking.

6.Weatherability. HDPE pipes for oil and gas contains finely divided carbon black to provide protection against degradation caused by ultraviolet rays from direct sunlight. Carbon black is the most effective single additive for enhancing the weathering characteristics of plastic materials. which is suitable for applications where there is long-term, direct exposure to ultraviolet light. This includes all surface, suspended, and above grade applications.

7.Low cost traceability systems (pipes and fittings) can be used to provide installation records.

HDPE Electro Fusion Fittings DN20-800mm PN10 and PN16 for Gas

| Injection Molded HDPE Electro Fusion HDPE Fittings | ||||

|

|

|

|

|

| HDPE 45° Elbow | HDPE 90° Elbow | HDPE Stub End | HDPE Tee | HDPE Reducer Tee |

|

|

|

|

|

| HDPE End Cap | HDPE Reducer | HDPE Coupler | HDPE Tapping Saddle | HDPE Branch Saddle |

Please Contact us to Get More Details, Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Specifications of High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings

EN 1555-2: Plastics piping systems for the supply of gaseous fuels – Polyethylene – Part 2: Pipes

ISO 4437-2: Plastics piping systems for the supply of gaseous fuels – Polyethylene – Part 2: Pipes

| ISO4437-2: Plastics piping systems for the supply of gaseous fuels-Polyethylene (PE)- Part 2: Pipes | ||||||||

| Dimensions in Millimetres | ||||||||

| Nominal Out-side diameter dn (mm) | Maximum out of roundness for straight pipes | Minimum Wall Thickness emina | ||||||

| SDR9 | SDR11b | SDR13.6 | SDR17b | SDR17.6c | SDR21 | SDR26 | ||

| 16 | 1.2 | 3.0 | 2.3d | |||||

| 20 | 1.2 | 3.0 | 2.3d | |||||

| 25 | 1.2 | 3.0 | 2.3d | 2.3d | ||||

| 32 | 1.3 | 3.6 | 3.0 | 2.4d | 2.3d | 2.3d | ||

| 40 | 1.4 | 4.5 | 3.7 | 3.0 | 2.4d | 2.3d | 2.3d | |

| 50 | 1.4 | 5.6 | 4.6 | 3.7 | 3.0 | 2.9 | 2.4d | 2.3d |

| 63 | 1.5 | 7.1 | 5.8 | 4.7 | 3.8 | 3.6 | 3.0 | 2.5d |

| 75 | 1.6 | 8.4 | 6.8 | 5.6 | 4.5 | 4.3 | 3.6 | 2.9d |

| 90 | 1.8 | 10.1 | 8.2 | 6.7 | 5.4 | 5.2 | 4.3 | 3.5 |

| 110 | 2.2 | 12.3 | 10.0 | 8.1 | 6.6 | 6.3 | 5.3 | 4.2 |

| 125 | 2.5 | 14.0 | 11.4 | 9.2 | 7.4 | 7.1 | 6.0 | 4.8 |

| 140 | 2.8 | 15.7 | 12.7 | 10.3 | 8.3 | 8.0 | 6.7 | 5.4 |

| 160 | 3.2 | 17.9 | 14.6 | 11.8 | 9.5 | 9.1 | 7.7 | 6.2 |

| 180 | 3.6 | 20.1 | 16.4 | 13.3 | 10.7 | 10.3 | 8.6 | 2.9 |

| 200 | 4.0 | 22.4 | 18.2 | 14.7 | 11.9 | 11.4 | 9.6 | 7.7 |

| 225 | 4.5 | 25.2 | 20.5 | 16.6 | 13.4 | 12.8 | 10.8 | 8.6 |

| 250 | 5.0 | 27.9 | 22.7 | 18.4 | 14.8 | 14.2 | 11.9 | 9.6 |

| 280 | 9.8 | 31.2 | 25.4 | 20.6 | 16.6 | 15.9 | 13.4 | 10.7 |

| 315 | 11.1 | 35.2 | 28.6 | 23.2 | 18.7 | 17.9 | 15.0 | 12.1 |

| 355 | 12.5 | 39.7 | 32.2 | 26.1 | 21.1 | 20.2 | 16.9 | 13.6 |

| 400 | 14.0 | 44.7 | 36.3 | 29.4 | 23.7 | 22.8 | 19.1 | 15.3 |

| 450 | 15.6 | 50.3 | 40.9 | 33.1 | 26.7 | 25.6 | 21.5 | 17.2 |

| 500 | 17.5 | 55.8 | 45.4 | 36.8 | 29.7 | 28.4 | 23.9 | 19.1 |

| 560 | 19.6 | 62.5 | 50.8 | 41.2 | 33.2 | 31.9 | 26.7 | 21.4 |

| 630 | 22.1 | 70.3 | 57.2 | 46.3 | 37.4 | 35.8 | 30.0 | 24.1 |

| a emin=en | ||||||||

| b Preferred series. | ||||||||

| c SDR17.6 series can be removed at the next revision of this Internation Standard. | ||||||||

| d Minimum wall thickness values greater than limits of 2.3mm, 2.4mm, 2.5mm and 2.9mm can be imposed for practical reasons in accordance with national requirements. See maunfacturer's files or national specification for advice. | ||||||||

High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings

Please find below HDPE pipes for different applications in accordance with different standards. Please clinck to view detailed products and specifications.

| HDPE Pipe for Fuel Gas Series | ||||

| HDPE Pipes for Gas | Standatd | Photo | ||

| Size | DN20-630mm(1/2 inch-24 inch) |  |

||

| HDPE Pipe for Gas | HDPE Pipe for Natural Gas | |||

| HDPE Pipe for Oil | ||||

| Standatd | ISO4437 | |||

| EN1555 | ||||

| GB/T15558 | ||||

| ASTM D3035 | ||||

| AS/NZS4130 | ||||

| GOST18599 | ||||

| ASTM D2513 | ||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

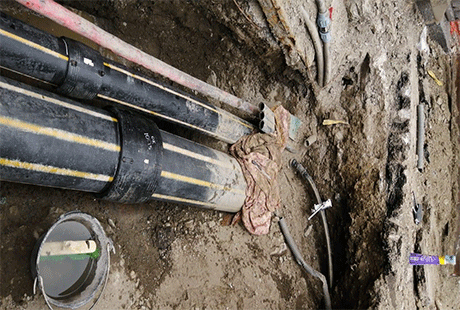

Application of High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings

- Oil transfer

- Water transfer

- Process water

- Methane Gas collection

- oil and gas gathering

- gas distribution system

- Mining

- Sour and wet gas lines

- Offshore oil & gas

|

|

| HDPE Pipes for Oil And Gas | HDPE Pipes for Natural Gas Transportation |

|

|

| HDPE Pipes for Liquefied Natural Gas | HDPE Pipes for Collection Of Methane |

High Density Polyethylene (HDPE) Natural Gas & Oil Pipes and Fittings

- Below are the HDPE Pipe specification, Pressure rating, Thickness, Dimension chart in different standard for water and fuels gas application for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@bingopipes.com. Mobile(WhatsApp): +86 155 15596408.

- ISO4437-2 Plastics piping systems for the supply of gaseous fuels-Polyethylene (PE)- Part 2 Pipes DownLoad

- EN1555-2 Plastics piping systems for the supply of gaseous fuels-Polyethylene (PE)- Part 2 Pipes DownLoad

- ASTM D2513 IPS HDPE Gas Distribution Pipe DownLoad

- ASNZS 4130 Series Pipes -Gas(Nominal Outside Diameter Series) DownLoad

HDPE Electro Fusion Fittings with bar code and tracking code DN20-630mm SDR11 and SDR17 for Gas Applications

Please Contact us to Get More Details, Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español