Products+

Latest Products

Contact Us

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Tel: +86 371 8618 0298

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

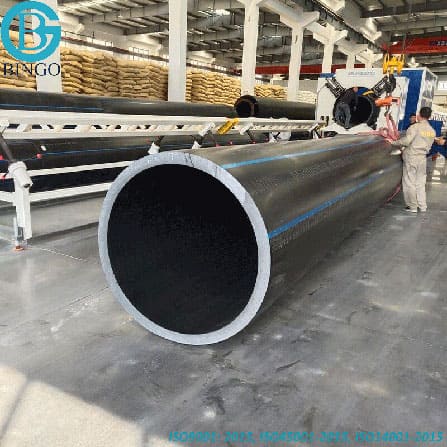

HDPE Pipes for Mining

For more than 30 years, polyethylene (PE) pipe’s unique mechanical properties, safety and reliability have made HDPE (High-density polyethylene) piping systems to be the he best choice for mineral and waste transfer in the mining industry.

- 1.Delivery: 10-30 days depending on the total quantity.

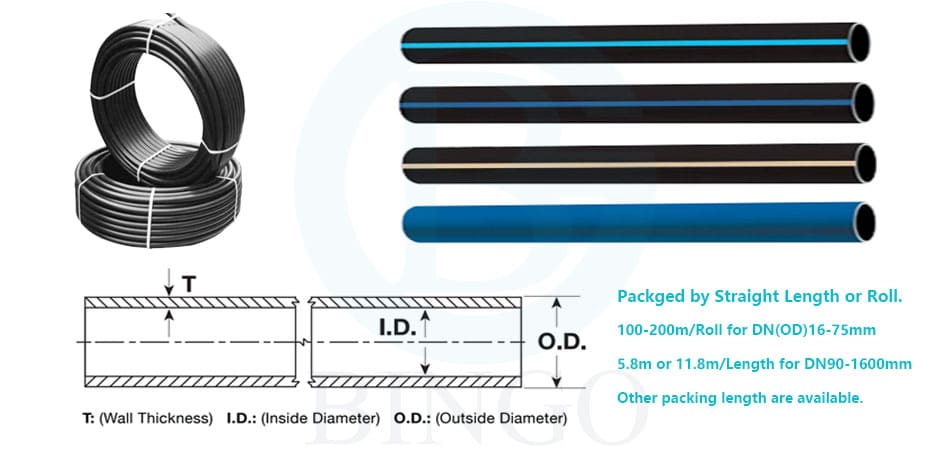

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene Mining Pipes and Fittings

| Products details information | |

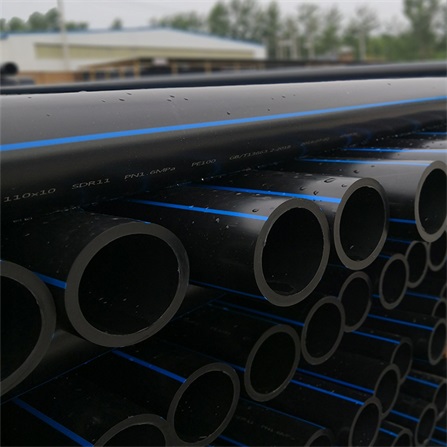

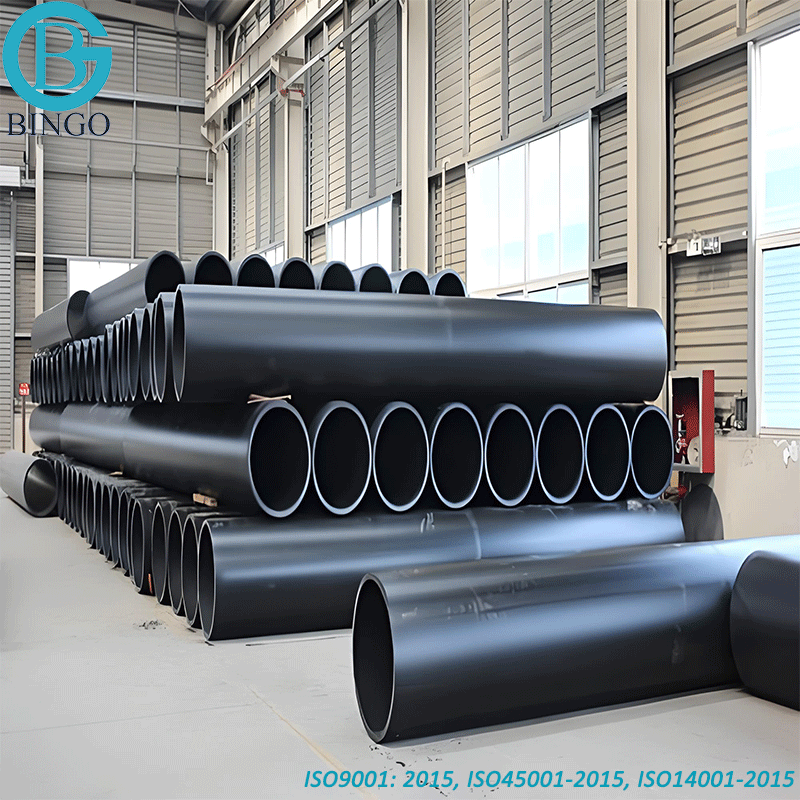

| Product name | High Density Polyethylene (HDPE) Mining Pipes |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | tailings slurry, Sewage disposal,Chemical transport, water supply in mining area... |

| Color | Black with blue stripes, black or others colors |

| Standards | ISO4427, ISO4437,EN12201,ASTM D3035, ASTM F714, DIPS... |

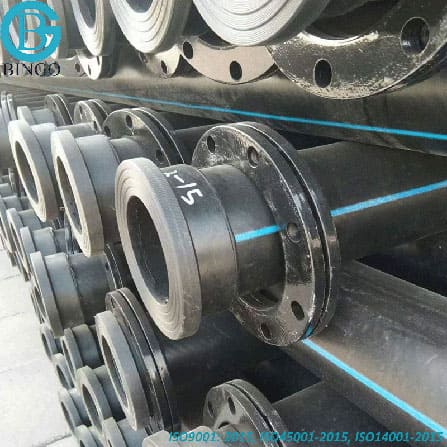

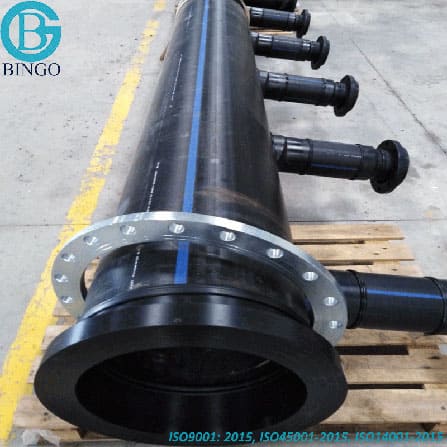

| Matching products | HDPE pipe fittings, Customized PE fittings, steel pipes, DI/ Steel backing ring flanges, Valves, flow gauge, water pump, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene Mining Pipes and Fittings

|

Historically, the pipes used in mining have been cement or steel pipes. These pipelines have problems such as short life, difficult to construct and easy to corrode. Nowadays, PE pipes are more and more popular in mining. They are not only easy to construct, but also resistant to acid and alkali corrosion, and the service life is much longer than other pipelines. PE pipes for mining are widely used for mine mortar, mine drainage, gas drainage pipes, positive and negative pressure air pipes, and so on. |

|

Historically, the pipes used in mining have been cement or steel pipes. These pipelines have problems such as short life, difficult to construct and easy to corrode. Nowadays, PE pipes are more and more popular in mining. They are not only easy to construct, but also resistant to acid and alkali corrosion, and the service life is much longer than other pipelines. PE pipes for mining are widely used for mine mortar, mine drainage, gas drainage pipes, positive and negative pressure air pipes, and so on.

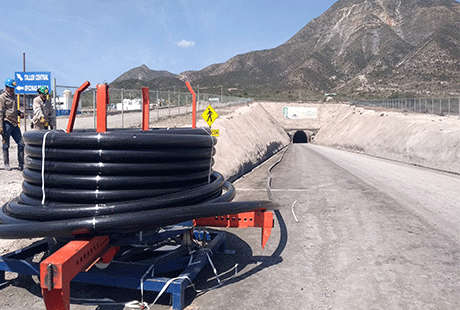

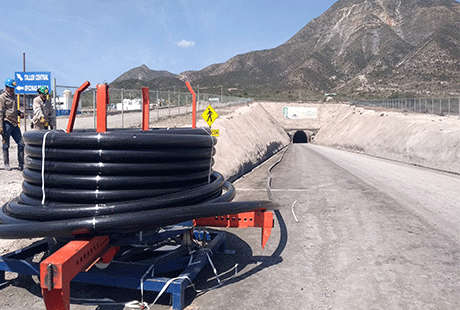

For rugged terrain, extreme weather and constantly changing on-site use condition, HDPE pipes are all proven products. Heat fused butt welding and socket fusion joints form an integral structure that can pull long-distance welded pipes from one area to another area. The flexibility, wear resistance and no leakage of the PE pipe make this product stand out in harsh using condition.

Bingo pipeline provide a wide variety of piping system, which had been authorized to use in many mining plant extracting hard coal and incombustible minerals (such as copper mine, lithium mine, gold mine, lead zinc ore), which is specifically designed for water supply systems, compressed air system, inert gas transmission system, hhydrotransport pipelines system, hydraulic filling distribution systems and many other applications. We are committed to producing and providing high-quality high-density polyethylene pipes and pipeline solutions for mining industries, including injection molded butt welding pipe fittings, electro fusion fittings, and welding machine equipment, fabricated fittings and flanges connection joints, etc. With our rich experience in pipeline industry, we have provided many complete solutions for the mining industry and won the high recognition of end users.

|

|

|

|

| HDPE Pipe for Gold Mining | HDPE Pipe for Copper Minerals | HDPE Pipe for Coal Minging | HDPE Pipe for Lithium Minerals |

Advantages of the High Density Polyethylene Mining Pipes and Fittings

When it comes to selecting pipe materials for mining applications, the two most important factors are security and reliability. The pipe must be rustproof, break-resistant and corrosion-free. It must safeguard the environment and protect the taxpayer. It must have a track record that professional engineers and installers respect.

High-density polyethylene (HDPE) pipe can meet and exceed these challenges and has several proven advantages for mining and industrial applications, including:

Chemical and Abrasion Resistance

PE pipe has proven itself over and over again in the variety of mineral process, ranging from low ph acids to high ph caustic solutions.

PE pipe has superb chemical resistance and is the material of choice in harsh chemical environments.

PE pipe is also abrasion resistant and is well suited for the solids environment in mining applications.

Pressure Surge Resistant

PE pipe for mining applications is semi-rigid to withstand high external loads as well as high internal pressure surges. Its flexible nature expands with pressure surges that increases the life of the pipeline and reduces maintenance costs.

Low Cost

The combination of flexibility and leak free joints allow for unique and cost effective types of installation methods that the rigid PVC and Ductile Iron pipes can't use with bell and spigot connections. These alternate installation methods (Horizontal Directional Drilling, Pipe Bursting, Sliplining, Plow and Plant, Submerged or Floating Pipe, etc.) can save considerable time and money in most applications.

Polyethylene pipe is produced in straight lengths up to 40 feet long and coiled in diameters up through 4-inch. Coiled lengths over 1,000 feet are available depending on size providing low cost installations.

Polyethylene is about one-eighth the density of steel. It does not require the use of heavy lifting equipment for installation.

Specifications of High Density Polyethylene Mining Pipes and Fittings

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 1.0 | 17.98 | 0.6 | 18.72 | 0.61 | 18.72 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 1.2 | 22.48 | 0.8 | 23.39 | 0.76 | 23.39 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 1.5 | 28.77 | 1.0 | 29.94 | 0.97 | 29.94 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 2.0 | 35.76 | 1.2 | 37.43 | 1.21 | 37.43 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 2.4 | 44.91 | 2.0 | 45.76 | 1.52 | 46.79 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Applications of High Density Polyethylene Mining Pipes and Fittings

- Solution Mining

- Heap Leaching

- Process Water

- Process Slurry

- Water Transportation

- Tailings Transportation

- Dust Suppression

- Mine Dewatering

- Pit Dewatering

- Depressurization

|

|

| HDPE Pipes for Mining Projects | HDPE Pipes for Mine Reclamation Project |

|

|

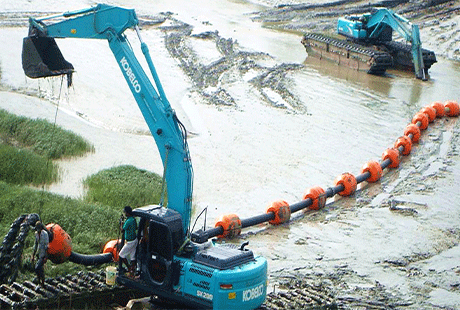

| HDPE Pipes for Pharmaceuticals And Bioindustry | HDPE Pipes for Slurry Dredging |

High Density Polyethylene (HDPE) Mining Pipes and Fittings

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español