Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

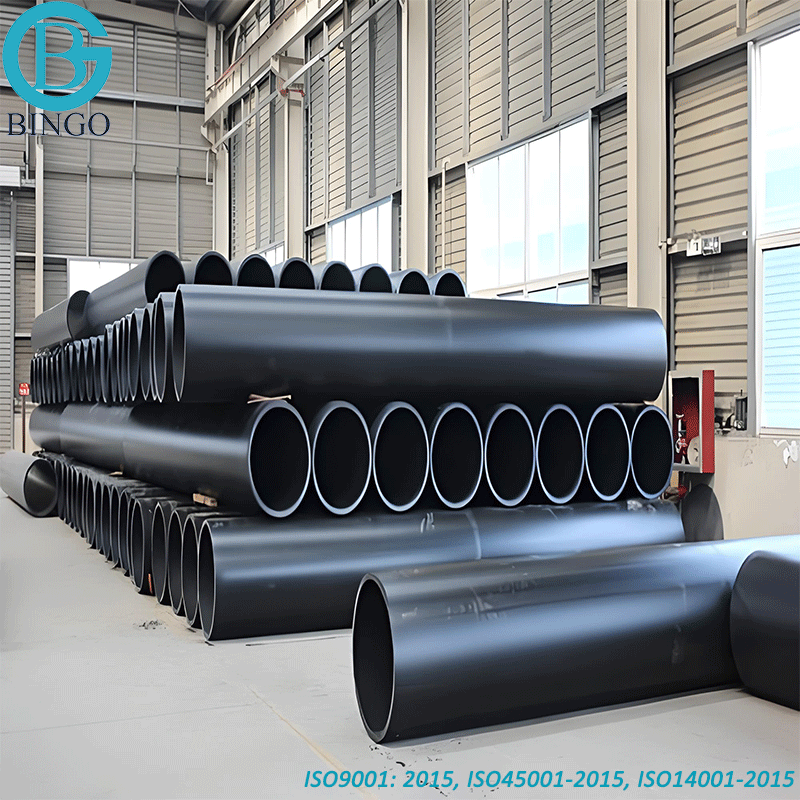

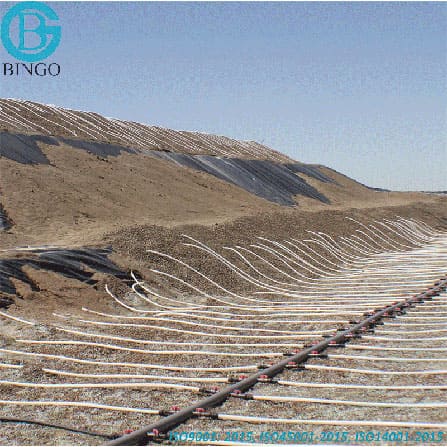

HDPE Pipes and Fittings for Irrigation

Irrigation pipes are made of high density polyethylene and medium density low density which is stabilized against UV rays. In this way, the pipe durability has been achieved, resisting the effect of sun, as the pipe bears the temperatures from -30˚C to +60˚C. These HDPE pipes are widely used in farming, for vineyard and fruit plantations, mining greening, garden landscape, and they are significantly applied in greenhouses.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: 11.8m/ Pcs for 40ft or 5.8m/ Pcs.

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection.

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) Irrigation Pipes and Fittings

| Products details information | |

| Product name | High Density Polyethylene (HDPE) Irrigation Pipes and Fittings |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | Irrigatin, drip ittigation, sprinkling irrigation, drinking water, fresh water, drainage, mining, dredging, marine, industry, chemical... |

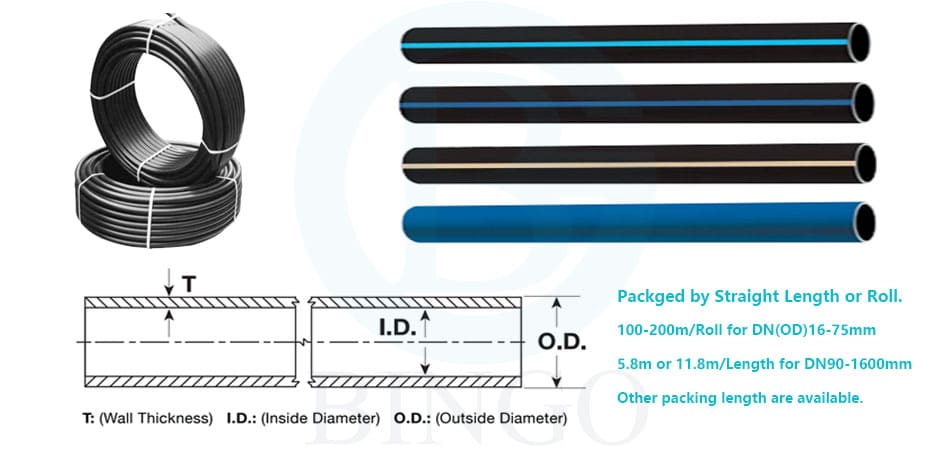

| Color | Black with blue stripes, black or others colors |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714 for water; ISO4437, |

| Matching products | HDPE pipe fittings, Customized PE fittings, floaters, Rubber hose, DI/ Steel backing ring flanges, dredging mud pump, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) Irrigation Pipes and Fittings

Irrigation pipes are used for operating pressure – PN of 4 bars, which is the common pressure for irrigation systems, but they can bear much higher operating pressure.

Irrigation pipes are used for working pressure -PN is 4 bar, which is a common pressure for irrigation systems, but they can bear higher working pressures.

If it is used as the main pipeline for long-distance water transportation, the main consideration is the water source, destination and transportation system. Ponds, reservoirs or lakes are usually the better choice for water source because it can be more easily managed to retain the required amount of water compared to other alternatives. Especially during the rainy season and drought, the flow of the river is uncertain. Without proper irrigation systems, this inconsistent climate will have an adverse effect on crops.

The diameter of the PE pipe used for the branch pipe of the irrigation system is usually from 20mm to 160mm, and the pressure is from 1 bar to 16 bar. The pipe used as the main pipe depends on the specific conditions. For details, please refer to the specifications of polyethylene water pipes.

Full range of PE irrigation pipes is available in Bingo pipeline-100m o 500m per coil, and 5.8 or 11.8m/ Length.

Advantages of High Density Polyethylene (HDPE) Irrigation Pipes and Fittings

Large temperature range: -40°C to +60°C. Strong resistance to weathering.

Good chemical resistance. Zero soil erosion, and Minimized fertilizer/nutrient loss due to localized application and reduced leaching

Long service life. Highly resistive to UV(ultraviolet) sun rays. The design life is more than 50 years.

Smooth internal surface. Small friction coefficient, smooth water flow, not easy to block, High water efficiency.

Does not conduct electricity. Insulation does not conduct electricity and is safe to use.

UV stabilized, perfect for outside use. Highly resistive to UV(ultraviolet) sun rays.

Relatively low cost. Water saving, less use of joints, low construction and installation cost.

Flexible. The pipe is flexible and can be coiled providing continuous long runs. In addition, it can bent to a minimum bending radius of up to 30 times the pipe’s outside diameter, often eliminating the need for fittings. Ability to irrigate irregular shaped fields and Leveling of the field not necessary.

Moisture within the root zone can be maintained with less water

Variation in supply can be regulated by regulating the valves and drippers

Foliage remains dry thus reducing the risk of disease

Specifications of High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 2.3 | 2.0 | 1.5 | 1.2 | 1.0 | 0.6 | 0.61 | 20 |

| 25 | 0.98 | 3.5 | 3.0 | 2.3 | 2.0 | 1.5 | 1.2 | 0.8 | 0.76 | 25 |

| 32 | 1.26 | 4.4 | 3.6 | 3.0 | 2.4 | 2.0 | 1.5 | 1.0 | 0.97 | 32 |

| 40 | 1.57 | 5.5 | 4.5 | 3.7 | 3.0 | 2.4 | 2.0 | 1.2 | 1.21 | 40 |

| 50 | 1.97 | 6.9 | 5.6 | 4.6 | 3.7 | 3.0 | 2.4 | 2.0 | 1.52 | 50 |

| 63 | 2.48 | 8.6 | 7.1 | 5.8 | 4.7 | 3.8 | 3.0 | 2.5 | 1.91 | 63 |

| 75 | 2.95 | 10.3 | 8.4 | 6.8 | 5.6 | 4.5 | 3.6 | 2.9 | 2.27 | 75 |

| 90 | 3.54 | 12.3 | 10.1 | 8.2 | 6.7 | 5.4 | 4.3 | 3.5 | 2.73 | 90 |

| 110 | 4.33 | 15.1 | 12.3 | 10.0 | 8.1 | 6.6 | 5.3 | 4.2 | 3.33 | 110 |

| 125 | 4.92 | 17.1 | 14.0 | 11.4 | 9.2 | 7.4 | 6.0 | 4.8 | 3.79 | 125 |

| 140 | 5.51 | 19.2 | 15.7 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 | 4.24 | 140 |

| 160 | 6.30 | 21.9 | 17.9 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 | 4.85 | 160 |

| 180 | 7.09 | 24.6 | 20.1 | 16.4 | 13.3 | 10.7 | 8.6 | 6.9 | 5.45 | 180 |

| 200 | 7.87 | 27.4 | 22.4 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 | 6.06 | 200 |

| 225 | 8.86 | 30.8 | 25.2 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 | 6.82 | 225 |

| 250 | 9.84 | 34.2 | 27.9 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 | 7.58 | 250 |

| 280 | 11.02 | 38.3 | 31.3 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 | 8.48 | 280 |

| 315 | 12.40 | 43.1 | 35.2 | 28.6 | 23.2 | 18.7 | 15.0 | 12.1 | 9.70 | 315 |

| 355 | 13.98 | 48.5 | 39.7 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 | 10.90 | 355 |

| 400 | 15.75 | 54.7 | 44.7 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 | 12.30 | 400 |

| 450 | 17.72 | 61.5 | 50.3 | 40.9 | 33.1 | 26.7 | 21.5 | 17.2 | 13.80 | 450 |

| 500 | 19.69 | 67.6 | 55.8 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 | 15.30 | 500 |

| 560 | 22.05 | 75.7 | 62.5 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 | 17.20 | 560 |

| 630 | 24.80 | 85.1 | 70.3 | 57.2 | 46.3 | 37.4 | 30.0 | 24.1 | 19.30 | 630 |

| 710 | 27.95 | 95.9 | 79.3 | 64.5 | 52.2 | 42.1 | 33.9 | 27.2 | 21.80 | 710 |

| 800 | 31.50 | 89.3 | 72.6 | 58.8 | 47.4 | 38.1 | 30.6 | 24.50 | 800 | |

| 900 | 35.43 | 81.7 | 66.2 | 53.3 | 42.9 | 34.4 | 27.60 | 900 | ||

| 1000 | 39.37 | 90.2 | 72.5 | 59.3 | 47.7 | 38.2 | 30.60 | 1000 | ||

| 1200 | 47.24 | 88.2 | 67.9 | 57.2 | 45.9 | 36.70 | 1200 | |||

| 1400 | 55.12 | 102.9 | 82.4 | 66.7 | 53.5 | 42.90 | 1400 | |||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

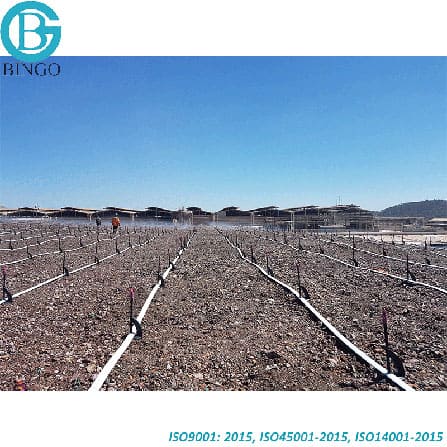

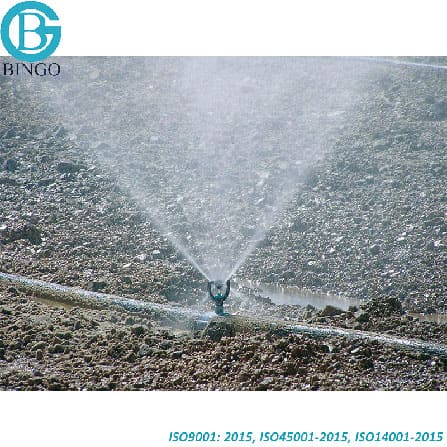

Application of High Density Polyethylene (HDPE) Irrigation Pipes and Fittings

- Polyethylene irrigation pipe is extensively used for drip and mini sprinkler system. Wisely made of high-grade virgin polyethylene, these pipes are highly resistant to UV rays, chemicals and fertilizers, used in agriculture. These pipes have smooth inner surface which minimizes frictional losses. These pipes are extensively used in various micro irrigation systems, water delivery systems, sprinkler stands and civil projects, such as micro sprinkler, online drip, mini sprinklers, jets and atomizer.

- Agriculture

- Micro irrigation

- Sprinkler irrigation

- Dripper applications

- Hydraulic automation applications

- Professional Landscaping

- Mine vegetation and protection & recovery

- Greenhouse planting, water, nutrient and precise growth of plants in capillary drip irrigation system.

- PE Irrigation Pipe, Drip tape, Coils or lengths available in Bingo pipeline, be sure to contact us reference bulk enquiry.

|

|

| HDPE Pipes for Irrigation | HDPE Pipes for Sprinkler Irrigation |

|

|

| HDPE Pipes for Irrigation And Rural | HDPE Pipes for Orchard Irrigation Systems |

Please Contact us to Get More Projects Cases, Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

High Density Polyethylene (HDPE) Irrigation Pipes and Fittings

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español