Products+

Latest Products

Contact Us

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Tel: +86 371 8618 0298

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

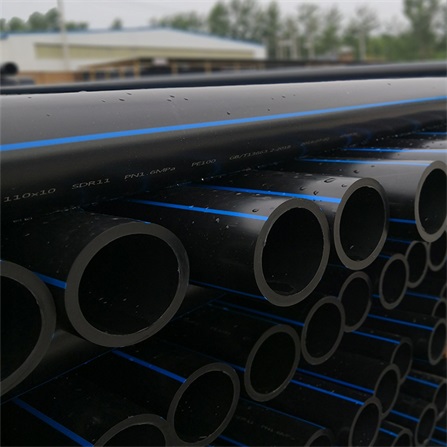

HDPE Pipes and Fittings for Fish Farming

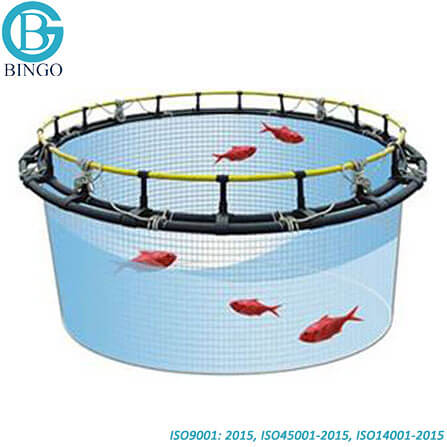

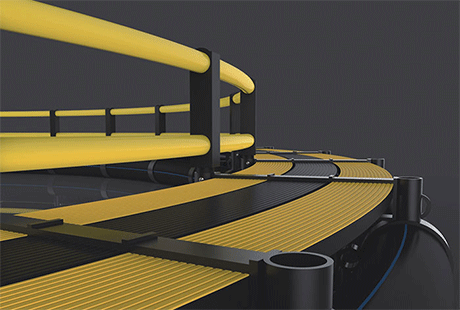

Bingo Deep sea HDPE floating fish cages system is made from HDPE tubular(HDPE pipes) and cage fittings, using foreign imported special-cage purpose polyethylene(HDPE) material.

- 1.Delivery: 10-30 days depending on the total quantity.

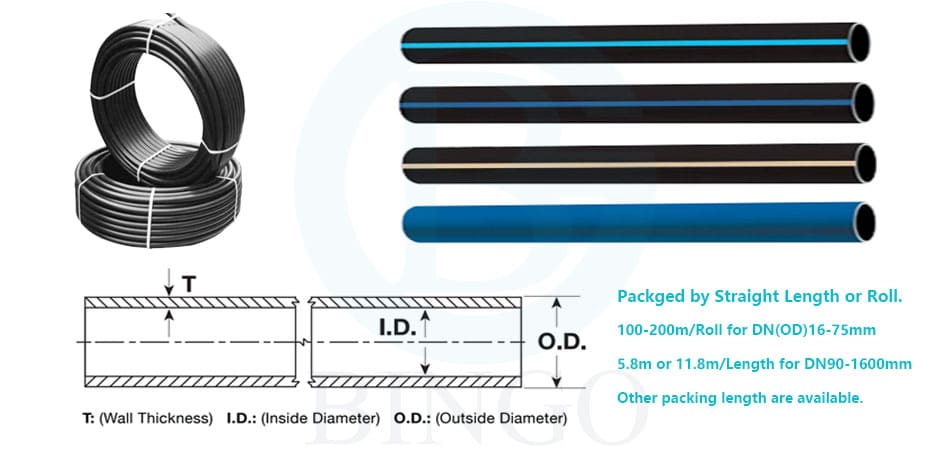

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene Fish Farming Pipes and Fittings

| Products details information | |

| Product name | High Density Polyethylene Fish Farming Pipes and Fittings |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN63-800mm(2 inch-32 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | HDPE dock systems, Aquaculture fish cage, water platforms... |

| Color | Black with blue stripes, black or others colors |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714 for water; ISO4437, |

| Matching products | HDPE pipe fittings, Customized PE fittings, Floaters, Fish Nets, Mooring System, Welding Machines and Tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

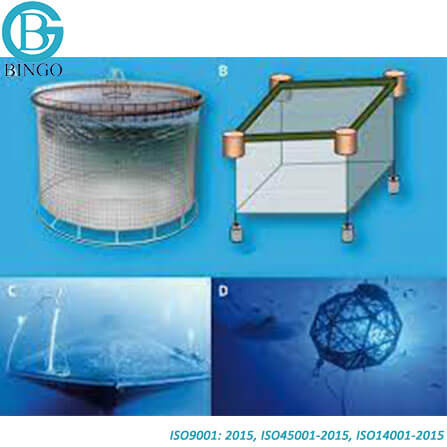

HDPE Cage Type

| Circular or Square HDPE Cage Type | |||

|

|

|

|

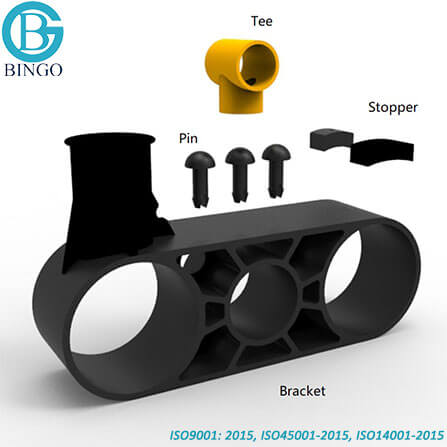

HDPE Cage Accessories

| Circular or Square HDPE Cage Type | |||

|

|

|

|

| Single HDPE Bracket | Single HDPE Bracket 2 | Double HDPE Bracket | HDPE Stand Column |

|

|

|

|

| HDPE Walk Way 1 | HDPE Walk Way 2 | HDPE Rope | HDPE or Nylon Fish Net |

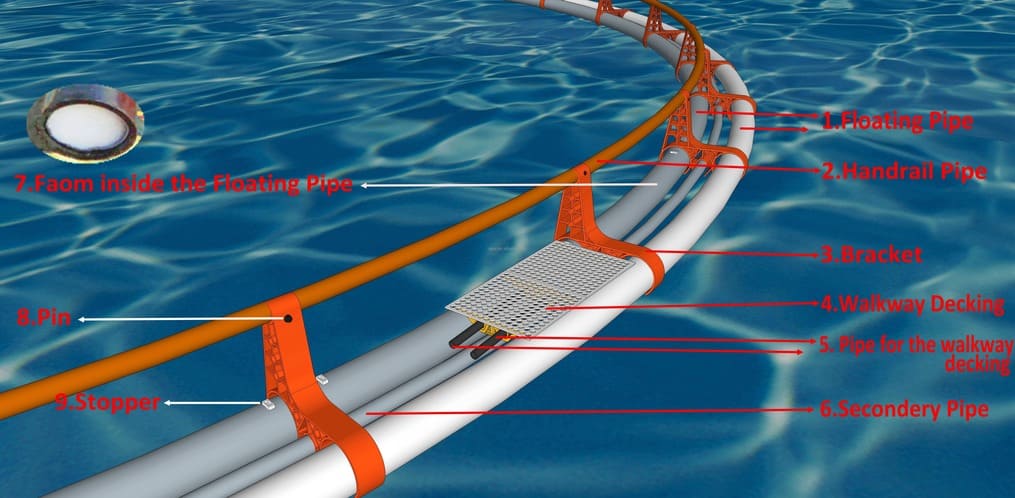

HDPE cage components

1.Fish Cage Frames

The fish cage are made of HDPE material, with outstanding heat resistance, chemical stability and mechanical performance. This module includes floating pipes, standing pipes, handrail pipes, brackets, and accessories.

Floating Pipe: The Key part of the pipe, two of a complete Fish cage, inside can be filled with foam which strengthen the Buoyancy

Handrail Pipe: higher than the floating pipe and water level, can be held by fisherman while feeding or fishing.

Bracket: usually every 2 meter of 1 pc, major part of supporting the fish cage structure, including L shape Bracket, triangle bracket, one-hole bracket and two-holes bracket etc., each has deferent features and advantages.

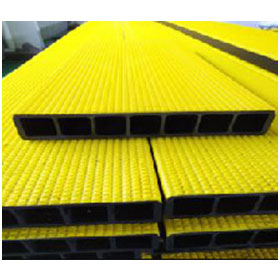

Walkway Decking: equipped for more convenient for feeding or fishing, can also be replaced by plank, not a must of a fish cage.

Pipe for the Walkway Decking: there are two small holes both in the bracket and the walkway decking, while two small pipes can combine the bracket and walkway decking to make it stronger.

Secondary Pipe: make the fish cage more stable.

Foam inside the floating pipe: usually only the inside floating pipe will use the foam to add Buoyancy.

Pin: combine the handrail pipe and bracket, also the bracket and floating pipe.

Stopper: being used at both side of bracket which give a swing space for the bracket. as storm and ocean current, a little space for bracket can bring more elasticity and longer life span for the fish cage.

2.Fish Nets of the Aquaculture fish cage

The fish nets are made of polyethylene or nylon material. Both are with outstanding chemical stability and mechanical performance. Polyethylene is cost-effective and nylon is with longer lifespan.

The module includes but not limited to predator net, inner net, and cover net for birds.

3.Mooring System of the Aquaculture fish cage

The mooring system is a highly customized module, depending on wind, waves, currents, water depth and seabed.

The module includes but not limited to anchors, ropes, chains, sinker, warning light, rings, and accessories.

4.Installation tools and welding machines

It includes the tools and welding machines to connect the pipes and fittings together, to make sure the strong enough of the whole HDPE cages system.

PE Net Fish Nets System

Polyethylene net includes inner Net, outer net, and cover net (bird-proof net). It is made of nylon, polyethylene, and ultra-high molecular weight meshes treated by anti-ultraviolet technology with international weaving technology. The net has high strength, Good safety, long service life, and according to customer needs, the net can be treated with anti-adhesion, which ensures that the effective anti-adhesion time of the net is prolonged by more than half a year under normal conditions and reduces the frequency of manual screen replacement. In addition, the underwater molding system designed by the company can effectively reduce the floating of the net and effectively raise more than 90% of the water body.

Advantages of High Density Polyethylene (HDPE) Fish Farming Pipes and Fittings

High intensity

Excellent flexibility

Corrosion resistant

Carbon black and antioxidants are added to the raw materials, with good UV resistance and antioxidant ability.

Strongly resistant to the storm

Long service life

Sufficient aquaculture volume with high efficiency and low comprehensive cost

Less pollution and high grade aquaculture water resulted in the perfect quality of the fish products, the good benefits and high returns.

Specifications of Deep sea HDPE pipe cages for fish farming

| ISO 4427 Pipe Series | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||

| ASTM F714 DR | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||

| Nominal Pressure PE 100 | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 63 | 2.48 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 |

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 |

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 |

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Applications of Deep sea HDPE pipe cages for fish farming

- Cage technology can not only be used for aquaculture(fish farming) in various water environments such as reservoirs, shallow seas, deep seas, harbors, lakes, etc., it can also be used for docks, hydropower stations, water parks, beaches, etc. In the shipbuilding industry, it is used to build small boats and rowing boats with simple structures. In tourism, leisure and entertainment, it is used to build various water platforms, water parks and various swimming pools.

|

|

| HDPE Pipes forfish Farming Cage | HDPE Pipes for Water Platforms |

|

|

| HDPE Pipes for Fish Cage | HDPE Pipes for Discharge Outfall Pipelines |

High Density Polyethylene (HDPE) Fish Farming Pipes and Fittings

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español