Products+

Latest Products

Contact Us

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Tel: +86 371 8618 0298

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

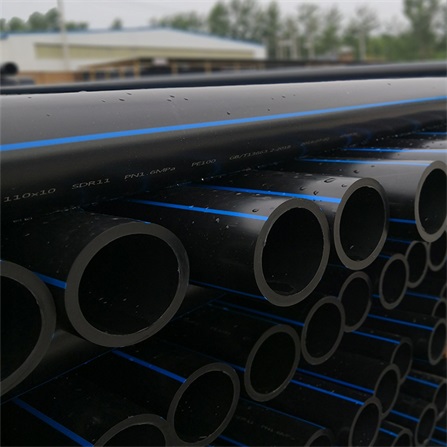

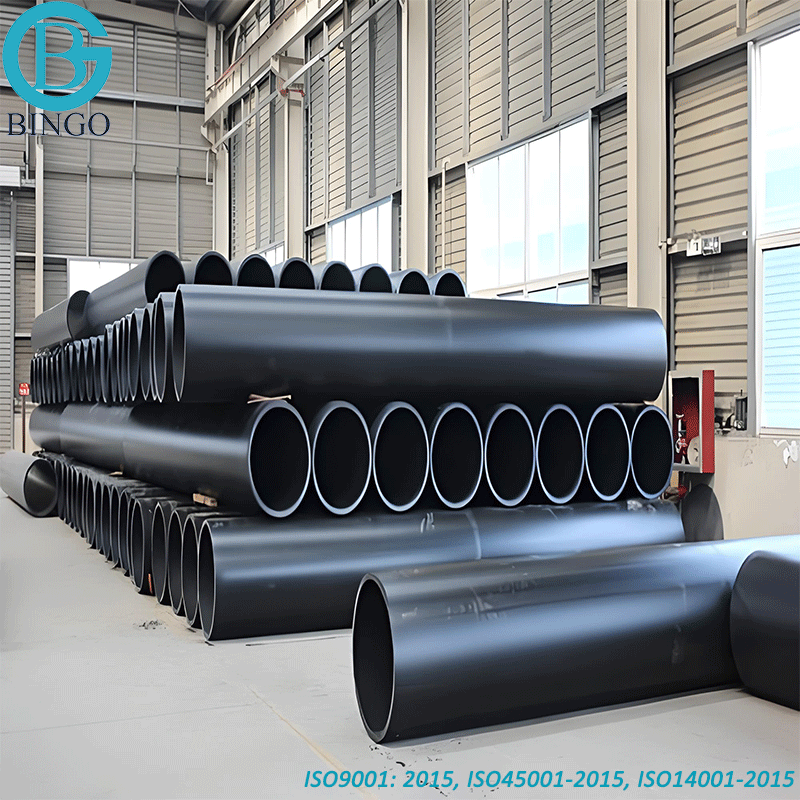

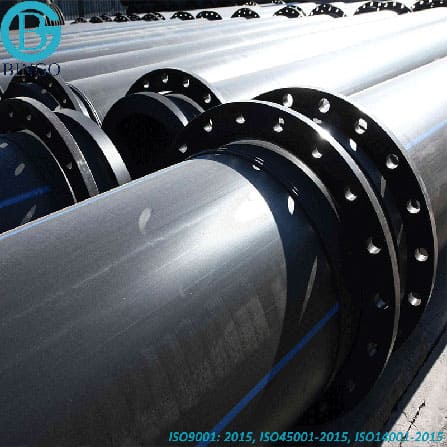

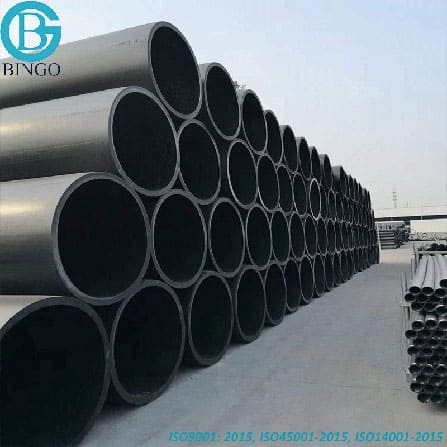

HDPE Pipes for Drainage/ Sewer

High-density polyethylene drainage pipe is a drainage system that can replace cast iron drainage pipes. Bingo sells a variety of polyethylene pressure pipe and fittings for drainage applications, as well as Non-pressure drainage pipe fittings. These non-pressure pipes are suitable for drainage and wastewater in industrial or building applications. Pressure drainage is mainly used in chemical, mining and other fields.

- 1.Delivery: 10-30 days depending on the total quantity.

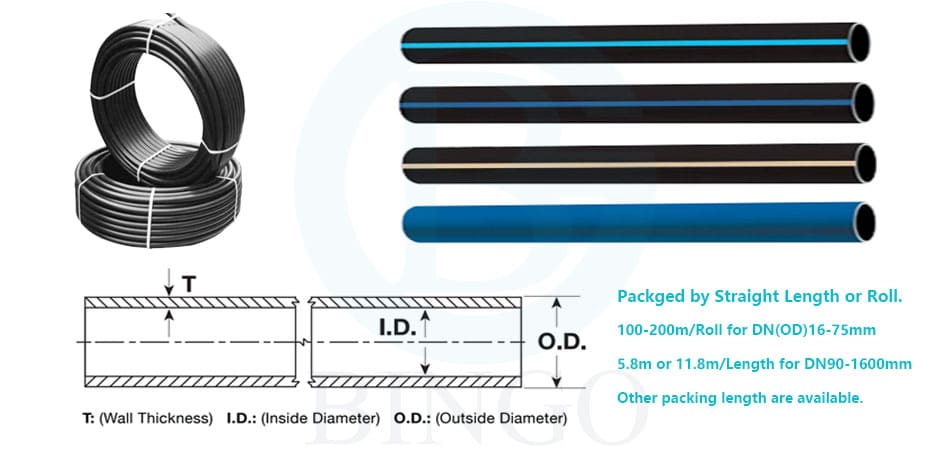

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) Drainage/ Sewer Pipes and Fittings

| Products details information | |

| Product name | High Density Polyethylene (HDPE) Drainage/ Sewer Pipes and Fittings |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN40-2000mm(1 1/4 inch-80 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | water treatment, Sewage disposal ... |

| Color | Black with blue stripes, black or others colors |

| Standards | ISO8770,ISO8772, ISO4427, EN12201, GOST18599, DIPS, ASTM D3035, ASTM F714... |

| Matching products | HDPE pipe fittings, Customized PE fittings, DI/ Steel backing ring flanges, Valves, flow gauge, water pump, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) Drainage/ Sewer Pipes and Fittings

The characteristics of the PE Drainage system such as the outstanding chemicals resistance, high temperature rating, flexibility and low noise make it the ideal selection for the residential and industrial buildings, laboratories, hospitals and hotels.

Bingo HDPE drainage system is the ultimate solutions for all type drainage including soil and waste, above ground, underground and chemical waste.

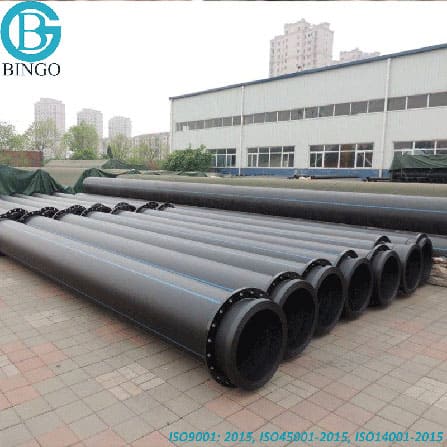

HDPE pipes and fittings for the drainage system are available in sizes from diameter 20-1600mm, can be joined by butt-fusion, electro-fusion, flanges or fabricated fittings by the pipes.

Durable. Due to its chemical stability and corrosion resistance, Bingo drain pipes and fittings are expected to last up to 50 years.

Advantages of High Density Polyethylene (HDPE) Drainage/ Sewer Pipes and Fittings

1. Long Durability.

Due to its chemical stability and corrosion resistance, Bingo drain pipes and fittings are expected to last for up to 50 years.

2. High flexibility.

Resulted from the high-quality virgin HDPE raw materials used to by BIngo to produce its pipes and fittings. The flexibility of the Bingo HDPE pipes and fittings guarantees crush resistance and ultimate performance when pipes and fittings are buried in Areas subjects to traffic and when passing through expansion joints.

3. High corrosion resistance.

Resulted from the basic properties of HDPE material that ensure high corrosion resistance.

4. High chemical resistance.

HDPE material has good resistance and excellent resistance to Alkaline and solvents. HDPE is also resistant to a wide range of chemicals, which renders the HDPE drainage systems the ultimate solution for chemical and industrial drainage networks. The system is insoluble in all inorganic or organic solutions at room temperature.

5. Low noise system.

With the help of the sound insulation function of HDPE material, which helps to reduce the noise level during system operation. This property makes Bingo HDPE drainage system ideal for installation in universities, hospitals, hotels, etc.

6. High resistance to extreme temperatures.

The Bingo HDPE drainage system can be safely used with fluids with temperatures up to 80°C. Short time loading at a temperature of up to 100°C is permissible. Bingo HDPE drainage system is also suitable for sub-zero temperature, and can elastically adapt to expansion and contraction caused by freezing and defrosting.

7. Strict quality control.

Bingo HDPE pipes and fittings are subjected to a number of in-house quality control tests during the production process and on the finished product. They are also subject to external testing by independent testing institutes to ensure the highest quality.

8. High impact resistance

Bingo HDPE is highly impact resistance, and therefore unbreakable at room temperature and sub-zero temperature.

9. Lightweight.

Bingo HDPE drainage system is light in weight compared to the traditional drainage system, which make it easy for handing, storage and transportation.

10. Smooth Internal Surface.

HDPE pipes and fittings are more resistance to solids build up or scaling.

Specifications of High Density Polyethylene (HDPE) Drainage/ Sewer Pipes and Fittings

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 1.0 | 17.98 | 0.6 | 18.72 | 0.61 | 18.72 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 1.2 | 22.48 | 0.8 | 23.39 | 0.76 | 23.39 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 1.5 | 28.77 | 1.0 | 29.94 | 0.97 | 29.94 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 2.0 | 35.76 | 1.2 | 37.43 | 1.21 | 37.43 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 2.4 | 44.91 | 2.0 | 45.76 | 1.52 | 46.79 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

We have completed HDPE Fittings and Welding Machine, tools to completed with our HDPE Pipe for your construction, One-stop supply, to meet your different requriement, save your cost and time, Please visit our HDPE Fittings Category and Welding Machine Category, Contact Us To get more details.

Please Send Email: sales@bingopipes.com. or Mobile:(WhatsApp): +86 155 15596408.

Applications of High Density Polyethylene (HDPE) Drainage/ Sewer Pipes and Fittings

- Drainage systems inside buildings. HDPE drainage system can be used in residential buildings, commercial buildings, industrial buildings and laboratories.

- External and underground drainage. HDPE drainage pipes and fittings can be installed outside buildings underground thanks to its flexibility and resistance to crush and abrasion.

- General infrastructure road and rail

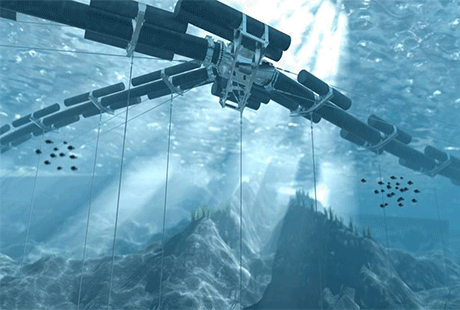

- Submarine pipelines and ocean outfalls

- Vacuum, pressure and gravity sewer system

- Slurry pipelines

- Upstream coal seam gas and water pipelines

- Culvert applications for Rural and agricultural markets

- Low head water transfer

|

|

| HDPE Pipes for Surface & Rain Water | HDPE Pipes for Drainage |

|

|

| HDPE Pipes for Subsea Pipeline Engineering | HDPE Pipes for Mining Applications |

High Density Polyethylene (HDPE) Drainage/ Sewer Pipes and Fittings

- Below are the HDPE Pipe specification, Pressure rating, Thickness, Dimension chart in different standard for water and fuels gas application for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@bingopipes.com. Mobile(WhatsApp): +86 155 15596408.

- Plastics piping systems for non-pressure underground drainage and sewerage-Polyethylene (PE) ISO 8772 DownLoad

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español