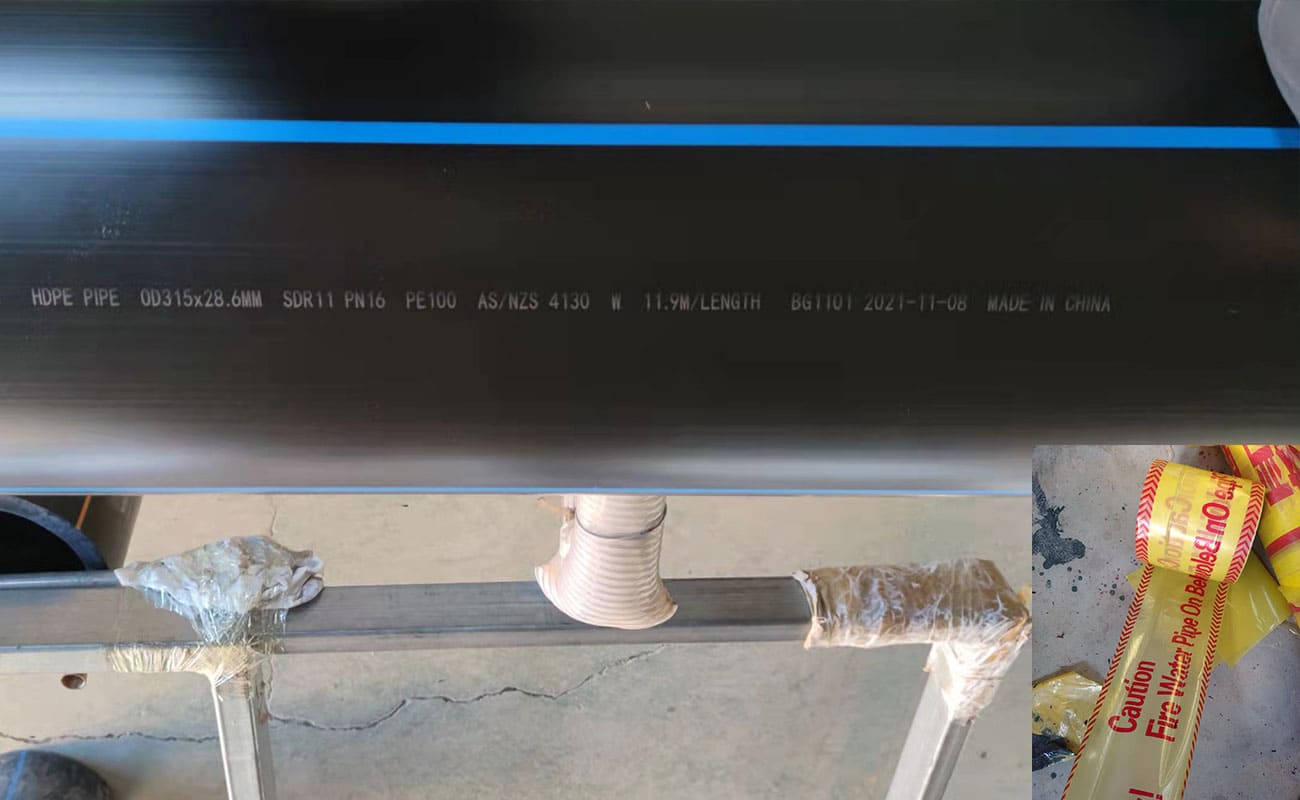

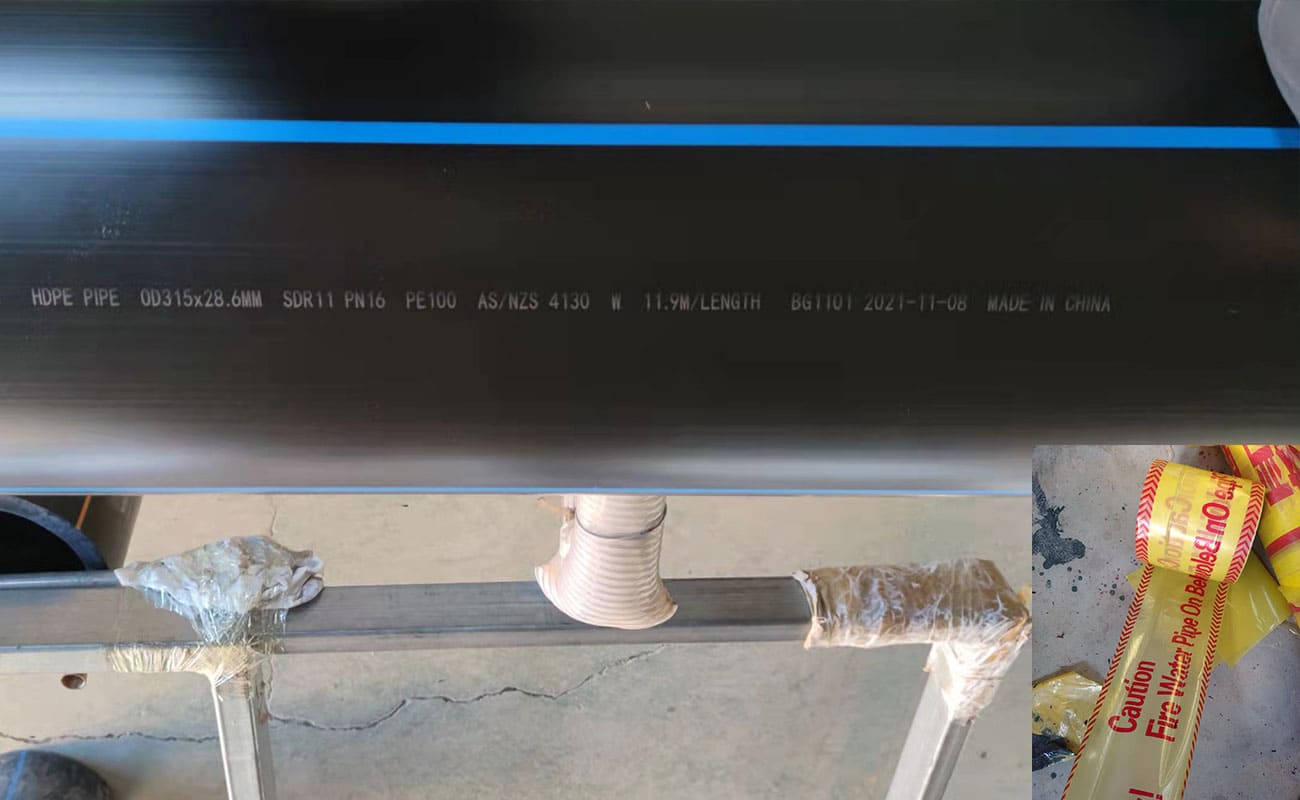

22 Dec . 2021

We just exported 3*40HQ containers of HDPE pipe and fittings to Australia markets, which are used for fire fight application.

Bingo Pipeline polyethylene piping products for underground firewater service provide high quality, high performance and durability to protect the environment, minimize costs, reduce maintenance and provide long-term, trouble-free service.

Why Use Polyethylene for Underground Fire Main?

Bingo Pipeline polyethylene piping has been used for underground fire mains for over 10 years in industrial and municipal firewater systems at refineries, chemical plants and manufacturing plants. Polyethylene piping has unique properties that make it the material of choice for firewater protection of company assets.

Benefits of the HDPE pipeline for fire fighting applications

- Complete systems of polyethylene pipe, fittings and joining.

- High strength and stiffness to withstand internal pressure and external loads.

- Chemical resistance to withstand corrosive chemicals (pH from 1 to 14) and aggressive soils.

- Toughness, light weight and impact resistance for lower-cost installation and narrower trenches for reduced excavation.

- Cold bending flexibility to follow “lay of the land” contours and reduce the need for directional fittings.

- A hydraulically smooth, non-wetting pipe bore that retains low flow resistance characteristics for the life of the system.

- Does not rust, rot, corrode or tuberculate.

- Non-conductive, cathodic protection NOT required, immune to stray ground currents for minimum long-term maintenance.

- Long-term, low resistance to fluid flow for reduced pumping and operating costs.

- Resistance to environmental stress cracking for long-term performance in harsh environments.

- A fully restrained system without external tie rods or restraints. Butt fusion, flanged and mechanical joint adapter joints are fully restrained to eliminate the need for thrust blocks and external joint restraints.

- Resilience to resist surge and water hammer.